That flashing DEF light on your JCB dashboard isn't a friendly reminder—it's a direct threat to your uptime. It’s the first sign of AdBlue crystallization, a problem where that damn urea solution forms hard, white deposits that slowly choke your SCR system. When that happens, you're looking at a full-blown JCB AdBlue DEF crystallization cleaning and pump replacement.

This is your battle plan to get that yellow iron back on the job and earning its keep, without getting locked out by the dealer's laptop.

What to Do When AdBlue Crystals Cripple Your JCB

Let's be clear: that DEF warning light is the first domino. Ignore it, and you’re staring down the barrel of limp mode, a full machine lockout, and a job site that's dead in the water. The culprit is almost always AdBlue crystallization—those nasty, crusty white deposits that clog injectors, lines, and the DEF pump itself.

This isn’t a minor annoyance. It's JCB's own finicky electronics putting a stop to your workday.

When this happens, you have two choices. Call the dealer, wait for their tech to show up with the Service Master laptop, and then swallow the bill. Or, you can diagnose and fix it yourself, right where the machine sits. This guide is for guys who prefer fixing it in the field.

Know Your Enemy: Urea Crystals

AdBlue, or Diesel Exhaust Fluid (DEF), is a specific blend designed to cut down emissions. Its precise chemical makeup is 32.5% urea and 67.5% deionized water, a ratio strictly mandated by ISO 22241 standards.

While that mixture is perfect for the SCR process, the moment it's exposed to air, the water evaporates. What's left behind are hard urea crystals that build up and wreak havoc. This crystallization is the root cause of most DEF headaches. It builds until fluid can't get through, starving the system and throwing fault codes the ECU simply can't ignore, leading to that dreaded forced Regen cycle that stops you in your tracks.

The real villain here isn't just the crystals; it's the downtime. Every hour a machine is down waiting for a dealer is an hour you're not making money. Taking control of the repair puts you back in charge.

Before you start tearing into the machine, you need a solid plan. Is it a simple clog, or is the pump completely shot? A good diagnosis saves you from throwing money at parts you don't need.

If you’re stuck trying to identify the right sensors, solenoids, or filters and want to bypass the dealer's wait times, a quick call can save you hours. You can get technician-led support by contacting Flat Earth Equipment.

Diagnosing Crystallization vs. Total Pump Failure in the Field

Before you start spinning wrenches, you need a solid diagnosis. A clogged DEF injector and a dead pump can throw similar codes, but one is a cleaning job and the other is a full replacement. Nothing burns time and money faster than putting a new pump in a machine that just had a crystal blockage.

When you're out on a job site, you don't have the luxury of the dealer's laptop. Your best tools are your own eyes and ears. A good field diagnosis starts with a walkaround, looking for the classic signs of JCB AdBlue DEF crystallization.

Reading the Signs: Clogs vs. Failure

Your first clue is almost always visual. Pop the engine cover and get a good, hard look at the SCR components.

- The DEF Injector: Zero in on the nozzle where it enters the exhaust. See any white, crusty residue? That's ground zero. If you've got buildup here, it's a safe bet your problem starts with a clog, not a fried pump.

- Fluid Lines and Connections: Follow the DEF lines from the tank, to the pump, and up to the injector. Check every connection for those same white, chalky stains. A pinhole leak exposes DEF to air and causes it to crystallize, and that gunk gets sucked right back into the system.

- The Pump Module: Give the area around the DEF pump housing a quick inspection. Leaks can happen here, too, leaving the same crusty evidence.

This five-minute check tells you a story. Heavy crystallization points to a blockage that needs cleaning. But if everything looks spotless and you're still getting pump-related codes, you’re probably looking at an internal failure.

The Key-On Sound Check

Next up, use your ears. Before you crank the engine, just turn the key to "on." Be quiet and listen to the DEF pump.

A healthy pump will kick off a priming cycle. You should hear a distinct whirring or buzzing for a few seconds as it builds pressure. If you hear that sound, the pump is getting power and is trying to work. This is a strong sign your real problem is a downstream blockage from crystallization.

Turn the key and hear absolute silence? No whir, no click? That’s a major red flag. It points to either a total pump failure or, more likely, an electrical problem. Think blown fuses, a bad relay, or a chewed-up wire. Always check the fuses first—it’s the cheapest fix in the book.

Fault Codes: A Technician's Translation

Those codes on the dash are a pain, but they're pointing you in the right direction. The dealer's manual gives you generic definitions, but here’s what they actually mean when you're on the job site.

| Dash Fault Code Group | What the Dealer Says | What It Really Means in the Field |

|---|---|---|

| DEF Pressure Low | "DEF delivery pressure not met." | The pump is running, but fluid isn't moving. 90% of the time, this is a clog in the filter, lines, or injector. |

| DEF Pump Circuit Open | "Loss of communication with pump module." | No power is getting to the pump. Check fuses, relays, and wiring before you condemn the pump. |

| DEF System Malfunction | "Generic SCR system fault." | The useless catch-all code. It usually pops up after a more specific code. Start with your visual and sound checks. |

Don't let a "Pump Circuit" code bait you into ordering a new pump. It's usually the simple stuff. A solid diagnosis in the field saves you a trip to the shop and gets that machine earning again. If signs point to a clog, your next step is a deep clean. But if the pump is dead silent and the wiring checks out, it's time for a JCB AdBlue DEF pump replacement, and you can grab one from Flat Earth Equipment without the dealer markup and wait times.

Cleaning AdBlue Crystal Buildup Without Damaging Components

Okay, you've done the checks. The pump has power, you hear it running, but you're still staring at those pressure codes. This is where the real wrenching starts. Time to get your hands dirty with a proper JCB AdBlue DEF crystallization cleaning.

This isn't just knocking off the white crust. This is a delicate operation. Rush it, and you're going to damage sensitive parts and be right back here in a few weeks, guaranteed.

Forget aggressive chemicals. Your best tool for dissolving these rock-hard urea deposits is warm deionized water. It's the primary component of DEF, and it's the only thing that will break down the crystals without corroding the plastics and seals. Never use tap water. The minerals are poison to an SCR system.

Breaking Down the Injector and Nozzle

First thing's first—pull the DEF injector. It’s usually held on by a couple of bolts on the exhaust stack. Pop off the electrical connector, disconnect the fluid line, and cap that line immediately. Contamination is your number one enemy.

Once it's off, the nozzle is probably caked in white crystals. Here’s the field-tested method:

- Soak, Don't Scrape: Grab a clean container and fill it with warm deionized water—not boiling, just warm. Submerge the nozzle end and let it sit. Be patient; this can take 30 minutes to a couple of hours.

- Gentle Cleaning Only: After it's soaked, use a soft nylon brush (an old toothbrush is perfect) to gently scrub away the loosened crystals. Under no circumstances use a wire brush or any metal tool. A single scratch will ruin the spray pattern forever.

- Inspect and Repeat: Hold the nozzle up to a light. You need to see daylight through every one of those tiny spray orifices. If anything is blocked, it's back in the soak.

While the injector is soaking, clean the injector port on the exhaust, making sure no debris falls into the pipe. You need a perfectly clean surface for a good seal.

Flushing the Lines the Right Way

With the injector cleaned, clear out the DEF line. Just reconnecting everything is asking for trouble. Grab your air compressor and a blow gun with a rubber tip.

Dial the pressure way down to a gentle 15-20 PSI. Anything higher risks blowing out internal seals. Drape a clean rag over the end of the DEF line, press the rubber tip against the fitting at the pump, and give it a few short bursts of air. You’ll see leftover fluid and gunk get pushed out into the rag.

This quick flush ensures the path is clear before you install your clean injector.

This cleaning process isn't new; it's been critical since JCB rolled out SCR systems. A German fleet study found that regular cleaning with warm water dropped crystallization-related failures from 32% down to a mere 10%. Skipping this is just asking for a breakdown. You can read more about how these crystals form and how to treat them on Wynns.eu.

Before you start, make sure you're geared up and working safe. You can brush up on the essentials in our article on heavy equipment operational safety.

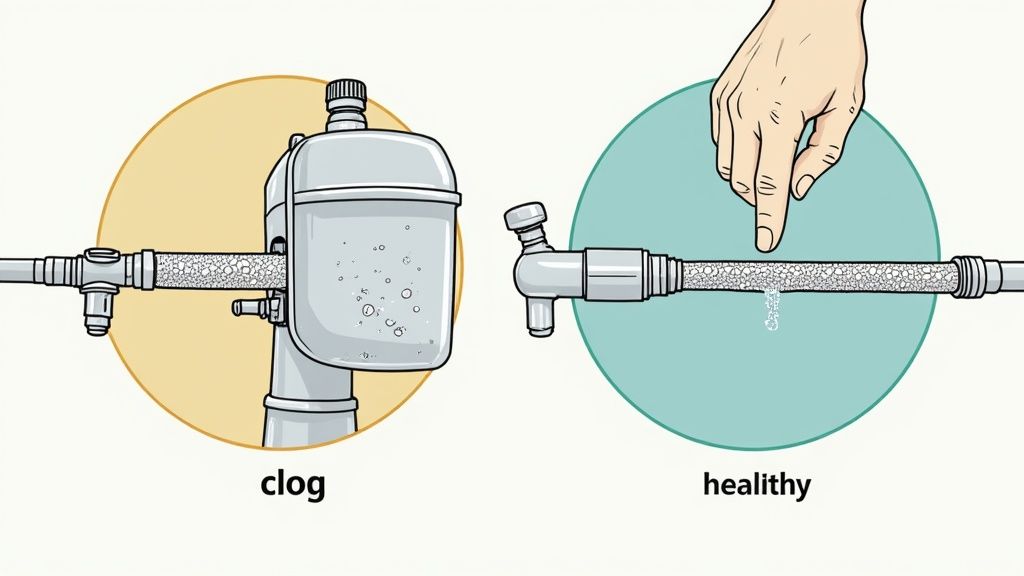

This image nails it—that's exactly how severe crystal buildup chokes off the AdBlue flow. Once everything is clean, bone dry, and reassembled, cycle the key a few times to let the pump prime. Now fire it up, run a full regen, and finally clear those codes for good.

Executing a Flawless JCB DEF Pump Replacement

You've cleaned the injector, flushed the lines, but that damn DEF pressure code won't die. The pump is dead silent, fuses are good. It's time to face it—the pump is toast. This is where the job gets serious, but it's nothing you can't handle right there in the field.

Replacing the DEF pump is the core of any major JCB AdBlue DEF pump replacement. Don't let it push you into calling the dealer. With the right parts and a methodical approach, you can have it swapped out without ever seeing their dreaded laptop.

The key here is to work clean. This isn't a job you can rush. The SCR system is finicky, and contamination is the fastest way to kill a brand-new pump.

Essential Tools and Parts for JCB DEF Pump Replacement

Before you turn a wrench, get your battle plan together. Having everything ready is half the fight.

| Item | Specification/Type | Pro Tip |

|---|---|---|

| New DEF Pump | OEM or high-quality aftermarket | Don't cheap out. A quality pump from a source like Flat Earth Equipment is your best insurance. |

| Safety Gear | Nitrile gloves, safety glasses | DEF is corrosive and irritating. |

| Cleaning Supplies | Compressed air, clean/lint-free rags | Contamination is the enemy. You want the area surgically clean. |

| Line Caps/Plugs | Assorted sizes | Non-negotiable for preventing spills and contamination. |

| Socket/Wrench Set | Metric | For mounting bolts and hardware. |

| Small Pick/Screwdriver | Flathead | For safely releasing electrical connector locking tabs without breaking them. |

| Zip Ties | Medium duty | Perfect for holding harnesses out of the way. |

| Catch Pan | Low profile | To catch any drips. |

Having these on hand turns a frustrating job into a smooth repair.

Locating and Prepping the Pump Module

First, you need to find the damn thing. On most JCB backhoes and telehandlers, the DEF pump module is tucked near the DEF tank, often mounted to the chassis. It'll be a compact unit with fluid lines and an electrical harness.

Before a wrench touches that machine, clean the entire area. Spotless. Use compressed air and a clean rag to blast away every bit of dust and mud so nothing can fall into the open lines.

Pro Tip: Take a quick picture of the pump and its connections before you disconnect anything. It’s a simple trick that has saved me more headaches than I can count. Think of it as your personal assembly guide.

Disconnecting and Removing the Old Unit

Alright, now for the careful part. Start with the electrical connector. Use a small pick to gently release the locking tab—don't just yank on it. Tuck the connector safely out of your way.

Next are the fluid lines. Have your line caps ready before you disconnect them. The second a line comes off, cap it. Do the same for the ports on the pump. This stops DEF from dripping everywhere and prevents dirt from getting into your system.

With everything disconnected, unbolt the pump assembly. Keep track of the bolts. The old pump is out. Now give the mounting area one final wipe-down before you bring in the new part.

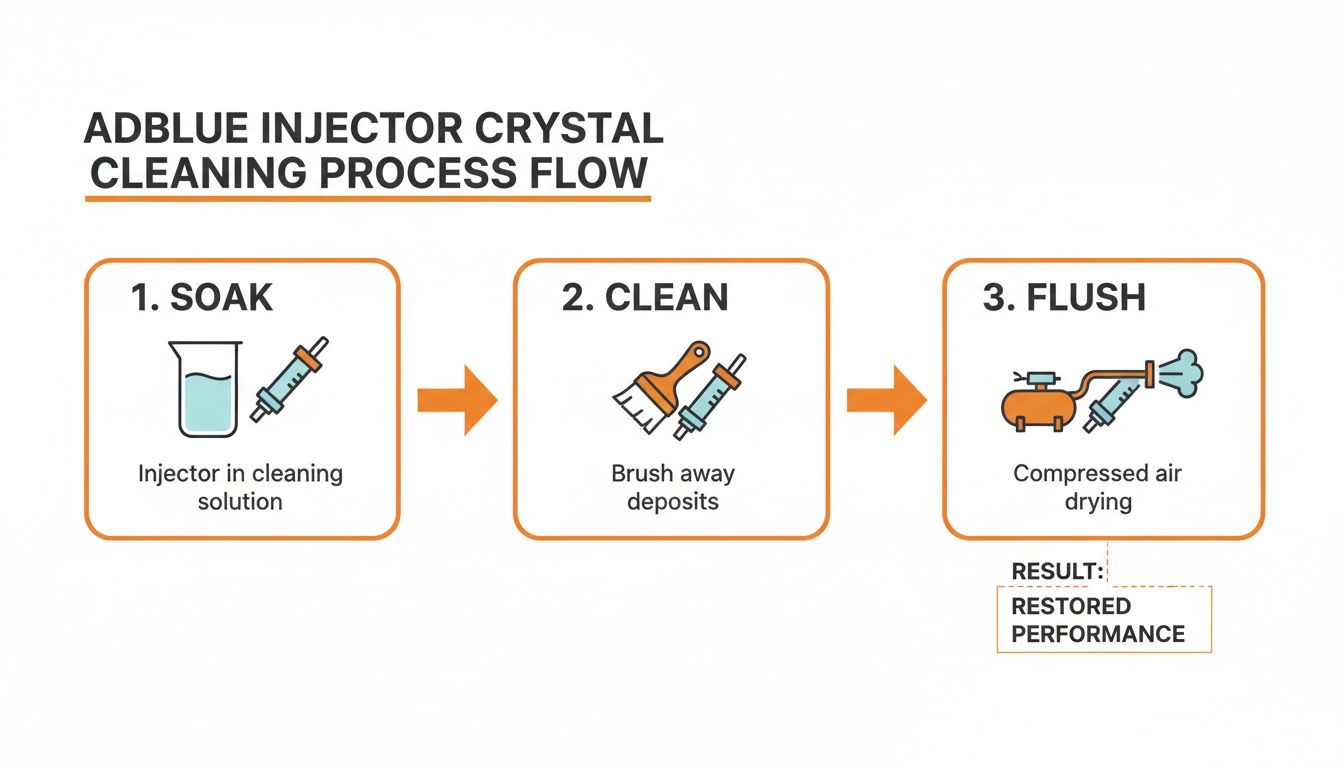

This process flow shows the basic steps for cleaning an injector, but the same principles apply to the entire pump replacement.

This visual breaks down the core cleaning process, hammering home the soak, clean, and flush stages vital for system health.

Installing and Priming the New DEF Pump

Installation is the reverse of removal, but your attention to detail has to be at 100%. Mount the new pump securely. Remove the caps from the lines and ports one by one, connecting them swiftly. Make sure each connection clicks or seats firmly. Finally, reconnect the electrical harness.

Now for the step the manuals barely mention: priming the system. Running a dry pump for even a few seconds can cause permanent damage.

Turn the key to the "on" position, but do not start the engine. You should hear the new pump whir to life. Let it run for about 30 seconds, then turn the key off. Wait 10 seconds, and repeat this key-on/key-off cycle four or five more times. This procedure forces DEF through the lines and purges any trapped air.

The global demand for SCR-equipped machines has made DEF pump failures a common and costly issue. A 2023 survey of 500 JCB operators revealed that 35% delayed routine cleaning, leading to average repair costs of $2,200 per pump. For machines with integrated tank units, that cost can skyrocket to $5,000. You can explore more data about the growing diesel exhaust fluid market on databridgemarketresearch.com.

Once the priming cycles are complete, start the engine. Let it idle while you check every connection for leaks. If it's dry, the machine is ready for a work cycle or a forced regen to clear old codes. You just performed a flawless JCB DEF pump replacement and kept the dealer's truck out of your yard.

Preventing Future Breakdowns to Keep the Dealer Away

Fixing a clogged injector or a fried pump gets the machine running today. The real win is making sure you never have to do this job again. Dealers love repeat customers for the same problem; I prefer machines that stay out on the job, making money.

Preventative maintenance isn't just a checkbox—it's the only thing standing between you and the dealer's service bay. A few smart habits are all it takes to stop JCB AdBlue DEF crystallization before it starts.

Your DEF Is Only as Good as Your Habits

Time and again, the number one cause of repeat SCR failures isn't a bad pump—it's bad DEF. This stuff has a shelf life, and it’s incredibly sensitive.

Treat your DEF supply with the same respect you give your fuel.

- Buy Fresh, Store Smart: Only buy DEF from high-volume suppliers in sealed, date-stamped containers. If a jug looks like it’s been collecting dust, leave it. Store your supply in a cool, dry place away from direct sunlight.

- No Contamination, Period: Use a dedicated, clean funnel just for DEF. A single drop of diesel, oil, or even rainwater is enough to poison the whole tank and kill a new pump.

- Keep It Sealed: The moment DEF hits the air, it starts crystallizing. Make sure your tank cap seal is in good shape and always screwed on tight.

Think of it this way: your SCR system is like the machine’s lungs. You wouldn't force it to breathe dirty air. Giving it old or contaminated DEF is just as bad, and you’ll get the same result—a machine that chokes up and quits.

These steps might seem obvious, but they're the most overlooked part of SCR maintenance. Techs who get this right spend their time working, not wrenching.

Additives and Inspections: Your First Line of Defense

For any machine that spends a lot of time idling or doing short runs, the exhaust never gets hot enough to keep the system clean. This is prime territory for crystallization. This is exactly where a quality anti-crystallization additive earns its keep.

It's cheap insurance. These additives change the surface tension of the DEF, making it harder for crystals to form on the injector nozzle. A few bucks for a bottle can easily save you from a multi-thousand-dollar repair bill.

Finally, make visual inspections part of your daily walkaround. When you’re checking the oil, take five extra seconds to glance at the DEF injector nozzle. See any white crust starting to form? That's your early warning. Clean it off now in minutes, long before it builds up and throws the machine into derate. It's about being proactive, not reactive. Outsmart the machine's electronics and stay in control. The folks behind Flat Earth Equipment started the company on this exact principle, a mission you can read more about on their company story page.

Q&A From the Trenches

You’ve put in the work, but questions always pop up when you're miles from the shop. Forget the textbook answers. Here’s the straight talk on the real problems you'll face with a JCB DEF system.

Can I Just Use Hot Water to Clean Everything?

No. Don't do it. While warm deionized water is perfect for cleaning a crystallized injector, you never want to flush the whole system with it.

Any water you leave behind will dilute the new DEF and throw fresh fault codes. Worse, in cold weather, that leftover water can freeze, crack your lines, and destroy the new pump you just installed.

The right way is targeted cleaning. Soak the clogged parts, then blow out the lines with low-pressure air until they are bone-dry. Keep water far away from the tank.

My Machine Is in Derate. Will a New Pump Fix It Instantly?

That's the million-dollar question. And the answer is almost always no. Replacing the pump solves the mechanical failure, but the ECU is still holding a grudge. It remembers the fault code and doesn't trust that you've fixed the problem yet.

Most of the time, the machine needs to see proof. This means running it through a full work cycle or a successful regen to convince the computer the repair is solid. After a few key cycles and some real work, the codes usually clear.

However, some stubborn fault codes get latched in there tight. They might require a forced regen or, in the worst-case scenario, the dealer's laptop to clear them. The key is to remember that a successful pump replacement is 90% of the battle. You fixed the root cause; now you just need to prove it to the machine's brain.

The biggest mistake I see guys make is expecting an instant fix. They swap the pump, the light stays on, and they immediately think they did something wrong. Be patient. Give the machine time to verify the repair.

What's the Biggest Mistake Guys Make on This Job?

Contamination. Period. It's the number one killer of new SCR components. This system is more sensitive than you can imagine. A single speck of dirt, a drop of grease, or a splash of tap water is a death sentence for a new pump.

The second biggest mistake is throwing parts at a problem without a proper diagnosis. A tech who sees a "low pressure" code and immediately orders a pump—without checking for a simple crystal clog first—is just wasting time and money.

- Work Clean: Always wear nitrile gloves and use clean, lint-free rags.

- Cap Everything: The second you disconnect a line, cap it. The moment you pull a component, cap the port. No excuses.

- Dedicated Tools: Have a funnel that is only ever used for DEF.

Do Those DEF Additives Actually Work?

The reputable ones absolutely do. They aren't snake oil. Look for a quality brand formulated to prevent crystallization. They work by changing the DEF’s surface tension, making it harder for crystals to form.

They’re cheap insurance, especially for machines that spend a lot of time idling or operating in cold climates. An engine that rarely gets its exhaust hot enough is the perfect breeding ground for crystals. Spending a few bucks on a bottle of additive can save you from a repair bill that runs into the thousands.

When you're stuck in the field and the dealer is weeks out, you need parts you can trust and expertise that gets you back to work. Flat Earth Equipment stocks the high-quality DEF pumps, sensors, and filters you need, with same-day shipping to keep you moving.

Get the right parts without the dealer runaround at https://flatearthequipment.com.