Your machine is a high-dollar paperweight because someone guessed on the forklift fork sizes. Getting these dimensions wrong means downtime, return shipping costs, and another day of lost productivity. This isn't some finicky JCB electronics problem the dealer needs a laptop to fix; this is about cold, hard steel and getting the right fit the first time.

Why Getting Forklift Fork Sizes Right Matters

Let's be blunt. While you're battling a JCB telehandler stuck in a regen cycle or waiting three days for a dealer tech with the magic "Service Master" laptop, the last thing you need is another preventable problem.

Ordering the wrong forks turns a simple replacement into a week-long headache. You’ve got a perfectly good machine sitting idle, not because of some infuriating AdBlue sensor, but because of a simple measurement error. This guide cuts through the dealer-speak and gets straight to what you need in the field—practical knowledge that keeps your yellow iron running and avoids the costly runaround.

The Cost of a Simple Mistake

Guessing on fork dimensions is more than an inconvenience; it's a direct hit to your bottom line. Every day a machine sits is a day it's not earning its keep. The consequences stack up fast:

- Downtime: The most obvious cost. The machine is out of commission until the correct parts arrive.

- Shipping & Restocking Fees: Sending back heavy steel isn't cheap, and suppliers will often charge a fee to take it back.

- Safety Hazards: An ill-fitting fork is a compromised lift. It creates dangerous instability that can lead to dropped loads, damaged equipment, or worse. For a deeper dive, review our essential guide on forklift safety principles.

The difference between a smooth lift and a catastrophic failure can be as little as a quarter-inch. Precision isn't optional—it's the only way to ensure the steel you order matches the steel on your machine.

From Custom Forging to Global Standards

The need for standardized forklift fork sizes isn't new; it has evolved right alongside the machines themselves. Back in 1917, when the first forklift patent was filed, forks were often custom-forged and pretty rudimentary.

Today, the global market runs on precision, with dimensions directly tied to load capacity. For instance, the forklifts that make up over 70% of the market—those under 5 tons—typically use 42-48 inch forks to handle the standard pallets that have been the backbone of logistics since the 1920s.

How to Measure Forks Accurately in the Field

Forget the glossy brochures and the clean-room specs from the dealer. When you're out in the yard with mud on your boots and a deadline breathing down your neck, you need to get it right with just a tape measure.

Ordering the wrong steel means your machine sits idle while you argue with a parts guy who’s never turned a wrench. This is how you measure forklift forks yourself and avoid that painful phone call.

This simple infographic breaks down the no-nonsense process: measure what you've got, order the right part, and get back to work without the dealer runaround.

Following these three steps eliminates guesswork and ensures the forks that show up will actually fit your machine's carriage. It's that simple.

Start with Thickness and Width

Before you even think about length, check the fork’s thickness. This is the absolute backbone of its strength. Measure it right at the heel—that's the vertical part that hooks onto the carriage. Now, slide your tape down the blade and measure it again.

If you see more than a 10% difference from wear, that fork is scrap metal. It has lost a massive amount of its rated capacity, and keeping it in service is just asking for a catastrophic failure. Don’t risk it.

Next up is the width. This isn’t just about fitting into a pallet; it’s about distributing the load’s weight evenly across the steel. Measure the width of the blade itself. It should be consistent all the way from the heel to where the taper begins at the tip.

Nailing Down the Length

The length is probably the most common measurement people get wrong. You don’t measure the whole piece of steel from end to end. You measure from the front face of the vertical back (the part that sits flat against the carriage) all the way to the tip.

Why does this matter so much? Because a fork that’s too long pushes the load center forward, completely wrecking the machine’s stability triangle. It’s the same principle as trying to carry a heavy bucket with your arms straight out—you’ll tip right over. "Close enough" can wreck equipment, damage the load, and get someone seriously hurt. Standard pallet forks are often 42 or 48 inches, but always measure what you have. Don't assume.

I’ve seen guys order 48-inch forks for a job that needed 42s, thinking longer is better. All they did was turn a stable 5,000-pound lift into a dangerously unbalanced machine that couldn't safely lift 3,500 pounds. Don't be that guy.

The Measurements Everyone Forgets

Now for the details that separate a pro from someone making a parts-return call. These are the measurements the dealer hopes you'll forget so you have to call them back.

- ITA Class (Hook Spacing): This is the most critical fitment spec. It’s not some dark art; it’s a simple distance. Measure from the top of the top hook to the bottom of the bottom hook. Common sizes are 16 inches (Class II), 20 inches (Class III), and 25 inches (Class IV). Get this wrong, and the forks won't even mount on the carriage.

- Carriage-to-Floor Height: This is the distance from the top of the lower carriage bar to the floor when the mast is fully lowered. It tells you if you need standard forks or full bottom taper forks to avoid gouging the ground on every pickup.

Finally, lay a straight edge along the top of the fork blade and another along the front face of the heel. There should be a perfect 90-degree angle. If it’s bent even slightly, the fork’s structural integrity is gone. It's junk. Taking these few extra minutes to measure accurately saves you weeks of downtime waiting on the right parts.

Decoding Forklift Classes and Load Capacity

Ever get the feeling the parts counter guy at the dealer wants you to think forklift classes are some mysterious code? It's their way of keeping you on the phone while they look up a simple number you could have measured yourself in thirty seconds.

A fork’s ITA class isn't magic. It's just a standardized measurement of the carriage height. We're talking about cold, hard steel—not a finicky JCB sensor that throws a code and derates your engine. Knowing the difference between a Class II and a Class III is the kind of practical knowledge that separates a quick swap in the field from a week of downtime waiting on the wrong parts.

The Three Classes You’ll Actually See

Forget the obscure stuff. In the real world of yellow iron and warehouse lifts, you're going to run into three main ITA classes. Grab your tape measure; this is all you need to know.

- Class II: Measure from the top of the upper hook to the bottom of the lower hook. If it's 16 inches, you've got Class II forks. These are the workhorses for most standard warehouse forklifts, typically rated for machines up to 5,500 lbs.

- Class III: If that same measurement comes out to 20 inches, you're looking at Class III. This is where you start getting into heavier equipment, usually in the 6,000 to 10,000 lb capacity range.

- Class IV: For the big stuff, that measurement will be 25 inches. This is Class IV, built for heavy-duty telehandlers and high-capacity lifts that don't flinch at serious weight.

Trying to hang Class II forks on a Class III carriage is a recipe for disaster. The hooks won't seat right, creating a massive safety hazard. The parts simply won't fit, and you'll be right back where you started, with a machine down and the clock ticking.

How Fork Class Connects to Raw Power

Fork class isn't just about fitment; it's a direct indicator of the fork's ability to handle punishment. A bigger class means thicker, wider, and tougher steel designed for a heavier machine. You wouldn't put pickup truck tires on a dump truck, and the same logic applies here. A heavier machine exerts more force, and it needs forks built to withstand it.

A heavy JCB telehandler requires robust Class IV forks because it’s lifting thousands of pounds to significant heights. The stress on that steel is immense. On the other hand, a standard warehouse lift moving pallets around at ground level operates just fine with lighter, more nimble Class II forks.

Don't ever let a salesman convince you to "upgrade" to a heavier class of fork than your carriage is built for. Mismatching components is a dangerous game that creates unpredictable failure points. Match the steel to the machine, every single time.

This direct link between fork dimensions and lifting power drives the entire industry. The 5-15 ton forklift segment, which relies on robust fork sizes of 60-84 inches long, 6-8 inches wide, and 2.5-3 inches thick, commanded over 40% share of the global market. Those beefy dimensions aren't for show; they're engineered to handle massive loads in construction and manufacturing, often paired with attachments like side shifters that make up 35% of the market. You can learn more from the findings on the forklift truck market.

Matching the right class and capacity isn't about following a complex chart locked away on the dealer’s laptop. It’s about understanding the fundamental connection between size, strength, and safety. Get this right, and you're not just replacing a part—you're ensuring your machine can do its job without putting your crew or your equipment at risk.

A Practical Chart for Standard Forklift Fork Sizes

This isn't some pristine chart you'll find in a service manual collecting dust on a shelf. This is a battle-tested reference built from years of wrestling with "yellow iron" in the field. It’s for recognizing the common forklift fork sizes you'll see on everything from a warehouse lift to a JCB telehandler, so you can order the right steel and get back to work.

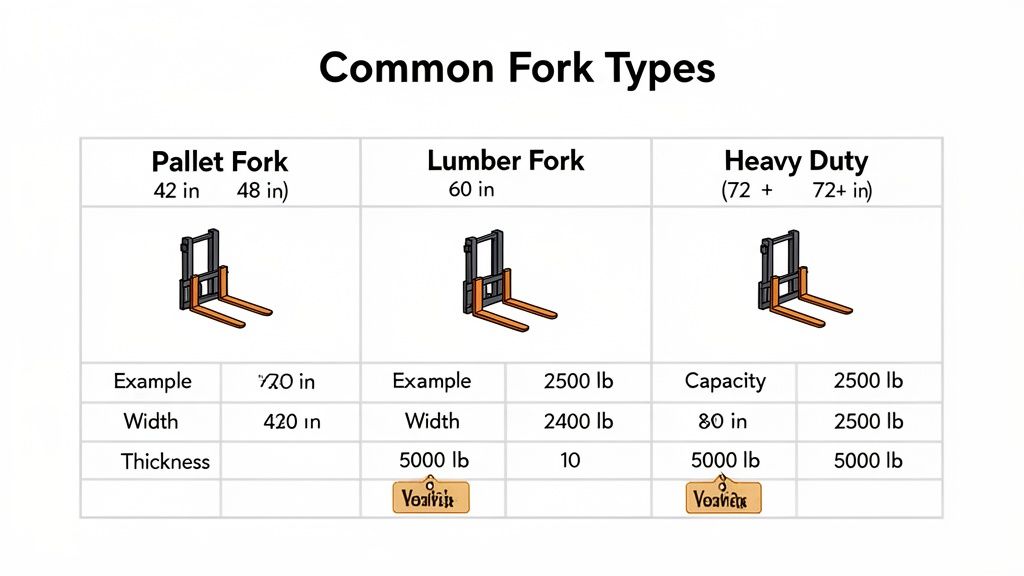

Forget calling the dealer and waiting for them to look up a part number. The patterns are simple once you see them. Standard pallet forks are almost always 42 inches or 48 inches long. Once you get into moving bundles of wood or longer materials, you'll start seeing 60-inch lumber forks. It's about spotting the setup from a mile away and knowing what you're dealing with.

This simple, direct chart connects fork dimensions to typical machine capacities. Think of it as your quick-glance guide on-site, saving you a trip back to the shop or a useless call to the parts desk.

Common Fork Sizes by Forklift Capacity

This chart isn't about memorizing every possible combination. It's about understanding the core relationship: as the machine gets bigger, the steel gets thicker, wider, and longer to handle the load.

| Forklift Capacity (lbs) | Common Fork Length (inches) | Common Fork Width (inches) | Common Fork Thickness (inches) | ITA Fork Class |

|---|---|---|---|---|

| Up to 5,500 lbs | 42" - 48" | 4" - 5" | 1.5" - 2" | Class II |

| 6,000 - 10,000 lbs | 48" - 72" | 5" - 6" | 2" - 2.5" | Class III |

| 11,000 - 20,000 lbs | 60" - 96" | 6" - 8" | 2.5" - 3" | Class IV |

| 20,000+ lbs | 96" and up | 8" and up | 3" and up | Class IV/Custom |

This chart covers 90% of what you’ll encounter. That 5,000 lb warehouse lift? It’s going to have 4-inch wide by 1.5-inch thick Class II forks. The 10,000 lb telehandler moving framing packages? You’re looking at beefy 6-inch wide by 2.5-inch thick Class III forks. See the pattern? It really is that straightforward.

Taper Tips: Standard vs. Full

The last piece of the puzzle is the fork tip. The dealer might make this sound complicated, but it's just about how easily the fork slides under the load.

- Standard Taper: This is the workhorse. It has a short, beveled tip and is what you’ll find on nearly every pallet fork. It's built for durability and everyday use.

- Fully-Tapered (or "Plywood Special"): These forks have a long, gradual taper, almost like a knife blade. They are designed to slip between tightly stacked materials like sheets of plywood or drywall without causing damage.

For standard pallet work, you need a standard taper, period. Ordering a full taper fork by mistake means you'll have a thinner, weaker tip that will wear out and bend much faster under the abuse of daily pallet handling.

Recognizing these patterns—length for the job, width and thickness for the capacity, and taper for the application—is what lets you bypass the dealer's parts lookup process. You have the knowledge. All you need is a reliable supplier like Flat Earth Equipment to get you the steel without the wait. Don't let a simple part replacement turn into a multi-day ordeal because you're stuck in a phone queue. Measure it, identify it, and order it yourself.

When to Replace Forks: The 10 Percent Rule and Other Red Flags

Steel gets tired. It bends, it wears, and eventually, it fails. Ignoring the signs of a worn-out fork is how you end up with a 4,000-pound load scattered across the shop floor. This isn't about some finicky sensor or a "regen" cycle stopping your machine; this is about preventing a catastrophic failure caused by fatigued metal.

The dealer will send you a glossy safety pamphlet, but out here, we rely on a daily walk-around and a sharp eye. The official OSHA line is the "10% rule," and it's the bare minimum you need to know.

The Critical 10 Percent Rule

Here’s the rule in plain English: if any part of your fork blade, especially at the heel, is worn down by 10% of its original thickness, it’s scrap metal. That might not sound like much, but that 10% wear translates to a nearly 20% reduction in safe lifting capacity.

You don’t need the dealer’s fancy ultrasonic tester to check this. All you need is a set of calipers. Measure the thickness of the vertical shank (the part against the carriage) and compare it to the thinnest part of the blade. If that blade is 10% thinner, it’s done. Keeping it in service is just gambling with your equipment and your crew.

Red Flags Beyond Simple Wear

The 10% rule is just the start. I’ve seen forks that passed the thickness test but were still a major liability. Here are the other, more subtle red flags you need to look for every single day.

- Surface Cracks: Check the top and bottom of the fork, paying close attention to the area around the heel and any welds on the hooks. Even a hair-thin surface crack is a sign of metal fatigue and an impending failure.

- Bent Blade or Shank: Lay a straight edge or a level along the top of the fork blade and the front face of the shank. There should be a perfect 90-degree angle. If there's any daylight under that straight edge, the fork is bent and its structural integrity is shot.

- Damaged Fork Hooks: The hooks are what keep the forks locked onto the carriage. Check for cracks, excessive wear, or any deformation. A damaged hook won't seat properly, creating an unstable lifting condition where the fork could slide right off the carriage mid-lift.

- Uneven Fork Height: When you lower the forks, are the tips at the same height? A difference of more than 3% of the fork's length indicates one is bent or sagging and needs to be replaced immediately.

Never, ever let someone talk you into a "quick weld job" on a cracked fork. Forklift forks are made from heat-treated, high-strength alloy steel. Hitting it with a welder destroys that heat treatment, creating a brittle weak point that's guaranteed to fail under load. It's not just a bad idea; it’s a massive liability and a direct violation of OSHA standards.

The Real Cost of Neglect

Properly inspecting and replacing forks isn't just about compliance; it's about preventing disaster. A catastrophic failure doesn’t just damage a load; it can destroy equipment, injure operators, and bring your entire operation to a standstill. The time and cost of a new set of forks are nothing compared to the fallout from an accident.

For managers, ensuring every operator is trained on fork inspection, as covered by OSHA 29 CFR 1910.178, is non-negotiable. The solution is simple: identify the damage early and order the right replacement. For more detailed safety checklists and best practices, check out our guide on forklift safety requirements in Texas. Don't wait for a service call to tell you what you can see with your own eyes.

Get the Right Steel, Minus the Dealer Hassle

You’ve done the hard part. You’ve wrestled a tape measure caked in mud, double-checked the ITA class, and you know exactly what capacity your machine can handle. Now you just need the steel—and you probably needed it yesterday.

The last thing anyone needs is to get stuck in the dealer’s voicemail loop, waiting for a parts guy to call back with an outrageous quote on a set of forks they don't even have in stock. That’s the old way. It’s slow. It’s the same runaround you get when a perfectly good JCB telehandler shuts down over a bad DEF sensor, and the official word is to wait three days for a tech with a laptop to show up.

The right way to do it now is to work with a supplier who actually gets it. One who understands that downtime is the enemy and keeps common forklift fork sizes on the shelf for the machines you actually use, like JCB, Toyota, and Hyster. This is about cutting through the red tape that costs you real money.

Stop Waiting and Start Working

Think about it this way: you wouldn't wait for the dealer to come clear a simple engine code if you had the tool to do it yourself. So why are you waiting for them to order a standard set of Class III forks? The short answer is, you shouldn't be.

Getting the right steel shouldn't be harder than diagnosing a finicky electrical system. It’s a simple transaction: you need a specific size, and you need it shipped fast from a hub that’s actually near you.

The goal is to get your machine back in the fight, not to let it sit idle waiting for a part that should have been on a shelf. Stop waiting on a "regen" cycle that won't complete, and stop waiting on a parts counter that doesn’t share your sense of urgency. It's time to get the right forks, get the machine running, and get back to work.

We stock the steel you need so you can get back to turning wrenches and moving dirt. If you're tired of the delays and need parts from a team that knows what it’s like in the field, reach out to Flat Earth Equipment directly. We’ll get you the right forks, minus the dealer hassle.

Frequently Asked Questions About Forklift Forks

When you're out in the field, you don't have time to dig through a manual. You need straight answers to get the machine back up and running. Here are the questions we hear most often from operators and mechanics—just the facts, no fluff.

How Do I Know What Class My Forklift Forks Are?

Forget the parts book for a second and grab your tape measure. This is a simple check you can do in less than a minute.

Just measure the vertical distance from the very top of the upper fork hook to the very bottom of the lower fork hook.

- If you get 16 inches, you've got Class II forks. These are the workhorses you'll find on most lifts up to about 5,500 lbs.

- If it's 20 inches, you're looking at Class III. These are for your heavier equipment, typically in the 6,000 to 10,000 lb range.

- A 25-inch measurement means you have Class IV forks, built for the really big stuff like heavy-duty telehandlers and high-capacity lifts.

This single measurement is the most critical piece of the puzzle for ordering replacements. If you get this wrong, the new forks won't even hang on the carriage.

Can I Use Longer Forks Than the Original Ones?

You can, but you're playing with fire. A forklift's capacity rating is calculated based on a specific load center—usually 24 inches out from the face of the carriage. When you bolt on longer forks, you push that load center further away from the machine.

This move drastically cuts the forklift's safe lifting capacity and creates a serious tipping hazard. It’s just like trying to carry a heavy toolbox with your arms stretched all the way out; you lose all your leverage and stability.

If you absolutely must use longer forks for a specific job, you have to consult the manufacturer's data plate for a de-rated capacity chart. Never just throw longer forks on and hope for the best.

What Is the Difference Between Standard Taper and Full Taper Forks?

This one's all about how easily the fork can slip under a load without tearing things up.

Standard Taper forks have a short, blunt taper right at the tip. They're the go-to, all-around choice for 99% of general pallet applications because they're built for durability and repeated abuse.

Full Taper forks, on the other hand, have a long, gradual taper that runs up a good portion of the blade, almost like a knife. You'll see these used for specialized jobs, like carefully sliding between tightly stacked materials such as paper rolls or sheets of plywood.

For everyday pallet work, the standard taper is what you want.

Using a full taper fork for heavy, routine pallet work is a big mistake. The thinner tip will wear down, bend, and fail much faster than a standard fork that was designed to take that kind of punishment. It's all about matching the tool to the job.

Why Can I Not Weld or Repair a Cracked Fork?

This is non-negotiable. Forklift forks are forged from a very specific high-strength steel alloy and then go through a precise heat-treating process to give them their incredible strength and flexibility.

The second you hit that specialized steel with a welder, you completely destroy the heat treatment. You create a brittle, unpredictable weak spot right where the fork needs to be the strongest. It might look "fixed," but it's really a catastrophic failure just waiting for the next heavy load to trigger it.

OSHA strictly prohibits any unauthorized repairs, welding, or heating of forks for this exact reason. It is never worth the risk to your equipment, the load, or your crew. Replacement is the only safe and legal option.

Stop waiting on the dealer's parts counter. Flat Earth Equipment stocks the common forklift fork sizes you need and ships them fast. Get the right steel without the runaround. Visit https://flatearthequipment.com to get your machine back to work.