When forklifts and people share the same workspace, the goal is to create a predictable, safe environment where everyone knows the rules of the road. A strong safety program isn't just about avoiding collisions; it's about building a system where heavy machinery and team members can coexist without incident. Think of it as installing a traffic light system, crosswalks, and speed limits right on your warehouse floor.

Understanding the Dangers of Shared Workspaces

Picture a busy downtown intersection with no stop signs, traffic lights, or painted crosswalks. The chaos and risk you’re imagining is the daily reality in many warehouses, distribution centers, and manufacturing plants. The interaction between a multi-ton machine with massive blind spots and an employee on foot is a recipe for disaster, making forklift and pedestrian safety a top-tier, non-negotiable priority.

An accident is never just a statistic. It carries devastating human and financial costs. For an employee, it can mean a life-altering injury or worse. For the business, it means downtime, legal exposure, shattered morale, and a significant hit to the bottom line. A proactive safety culture isn't about checking a compliance box—it's about protecting your most valuable asset: your people.

The Real-World Risk of Collisions

The danger is far more common than most managers think. The statistics paint a grim picture. A shocking 36% of all forklift-related deaths involve pedestrians, a clear sign of just how vulnerable people are when they’re on foot.

On top of that, pedestrians are caught up in roughly 20% of all non-fatal forklift accidents. These aren't minor bumps; the median time away from work for these injuries is 20 days, a longer recovery than for many other forklift-related incidents. You can dig into more of this data directly from the Bureau of Labor Statistics.

This data proves one critical point: just telling people to "be careful" is not a strategy. An effective safety program has to be built on a foundation of tangible, enforceable systems.

Pillars of a Strong Safety Program

Building a truly safe environment isn't about focusing on one thing. It demands a multi-faceted approach that looks at the entire operational ecosystem—not just the operator or the pedestrian in isolation, but how they interact within their shared space. The core pillars of an effective program always include:

- Worksite Hazard Identification: Proactively walking the floor to find and flag risks like blind corners, cluttered aisles, and high-noise areas where warnings might be missed.

- Traffic Management and Controls: Putting physical and administrative rules in place, such as clearly marked walkways, speed limits, and no-go zones for pedestrians.

- Comprehensive Training: Making sure both forklift operators and pedestrians understand their specific roles and responsibilities in keeping the entire facility safe.

By building on these key areas, you can transform your worksite from an uncontrolled free-for-all into a well-managed system where everyone knows the rules. This guide will walk you through the actionable steps to build and reinforce each of these pillars.

Conducting a Worksite Hazard Audit

Every warehouse, dock, and factory floor has its own set of safety challenges, many hiding in plain sight. To really move the needle on forklift and pedestrian safety, you have to learn to see your facility through a new lens—one that spots not just the obvious danger of a collision, but the subtle risks that lead up to it. We call this a worksite hazard audit.

Think of yourself as a detective arriving at a scene before a crime has happened. Your job is to find the clues—the blind corners, the noisy areas, the ignored safety rules—that could eventually lead to a serious incident. A methodical audit gives you a clear roadmap for what to fix first.

And this isn't just about compliance; it's about saving lives. In the United States, an average of 87 workers are killed annually in forklift accidents. What's truly sobering is that this number has jumped by nearly 30% over the last decade. Globally, the toll is staggering, with around 96,700 forklift-related injuries each year. You can dig deeper into these forklift accident statistics to see the full picture.

Identifying Environmental Hazards

The first place to look is the environment itself. These are often the easiest hazards to spot, but they're also the easiest to get used to and ignore. Your audit needs to take a hard look at anything in the workspace that messes with visibility, creates obstacles, or sends mixed signals to your crew.

Start with the lighting. Are there dimly lit aisles? Shadowy corners where a person could easily go unnoticed? What about glare from big windows or overhead lights that could blind an operator for a split second? Poor lighting is a silent partner in many accidents, making it impossible for operators and pedestrians to make that critical eye contact to confirm they've seen each other.

Next, just listen. Can you actually hear a forklift's horn or backup alarm over the constant roar of machinery, conveyor belts, or HVAC fans? In a noisy plant, those auditory warnings are basically useless. All you're left with are visual cues, and if the lighting is bad, you've got a recipe for disaster.

Keep an eye out for other environmental traps:

- Blind Corners and Intersections: Any spot where an operator’s line of sight is completely blocked until the last possible second.

- Obstructed Pathways: Pallets, tools, or trash left in aisles can force people to step right into a forklift's path.

- Uneven or Slippery Surfaces: Potholes, cracks, oil spills, or water can make a forklift jostle its load or cause someone to slip and fall at the worst possible moment.

Analyzing Equipment and Operational Factors

Once you've mapped out the physical risks, it's time to look at the machines themselves and the "rules of the road" that govern how they move. This part of the audit is all about the forklifts and whether there's a real traffic plan in place—or if it's just a free-for-all.

Start with your fleet. Do all the safety features actually work? Check the horns, backup alarms, and warning lights on every single machine. A broken horn isn't a minor maintenance issue; it's a critical failure of your safety system.

"A well-maintained forklift is a predictable forklift. When operators can trust their equipment to function correctly—from the brakes to the warning horn—they can focus their full attention on navigating the worksite and avoiding hazards."

Beyond the hardware, observe the traffic flow. The biggest red flag is the complete absence of a clear, enforced traffic management plan. Watch how forklifts and pedestrians interact. Are there speed limits? Are there designated walkways and "no-go" zones for people on foot? Without these rules, you're leaving safety up to individual judgment, which is a gamble you can't afford to take.

Ask yourself these key operational questions:

- Are forklift routes separated from pedestrian paths whenever possible?

- Do we have clear, visible signs for stop points, speed limits, and pedestrian crossings?

- Are operators consistently using their horns when approaching intersections and blind corners?

Evaluating Human Factors and Behaviors

The final piece of the audit is the most unpredictable and the most important: people. Complacency, distraction, and a simple lack of awareness can tear down the best-laid safety plans. This is where you have to be a keen observer of human nature.

Get out on the floor and just watch. Do you see pedestrians walking with their heads buried in their phones? Are they carrying boxes that block their view? Do they stick to the marked crosswalks, or do they constantly take shortcuts through busy forklift zones? These are signs of complacency—that dangerous feeling that "it won't happen to me."

Pay just as much attention to the forklift operators. Are they rushing to hit a quota, causing them to drive too fast or take corners on two wheels? Do they always check that their path is clear before moving, or do they sometimes drive with their view obstructed by a large load? These behaviors often signal that production pressure is winning out over safety protocol. Seeing these patterns is the first step toward fixing them with better training and a stronger safety culture.

Implementing Effective Safety Controls

Once you’ve audited your worksite and pinpointed where the dangers are, it’s time to start building a safer environment. The best safety measures are the ones you design right into the workflow and physical space. They make safe behavior the easiest, most natural choice.

These safeguards fall into two powerful categories: engineering controls and administrative controls.

Think of engineering controls as the physical architecture of safety—like building guardrails on a bridge. They physically separate people from hazards. Administrative controls, on the other hand, are the rules of the road—the traffic laws everyone follows to cross that bridge safely. Put them together, and you've got a robust system for forklift and pedestrian safety.

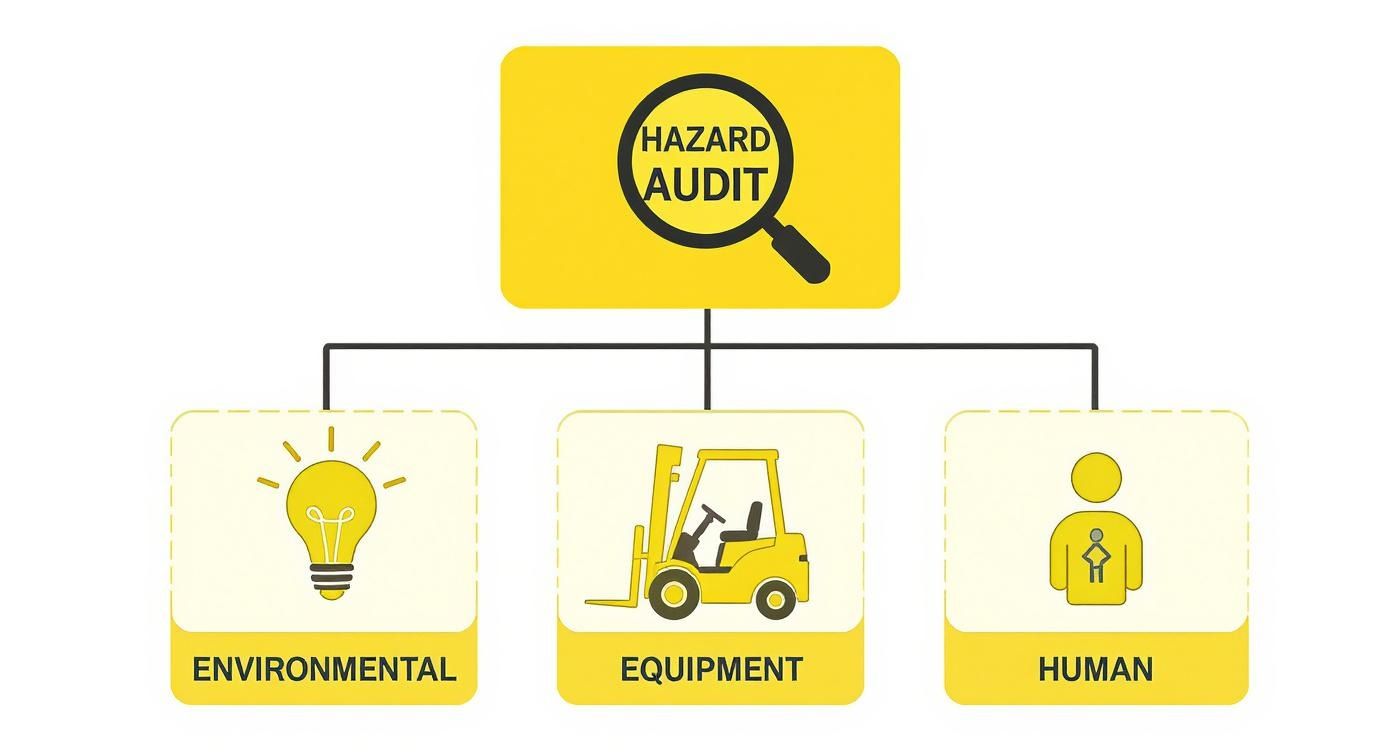

The infographic below breaks down the key areas to investigate during a hazard audit, which will inform the controls you put in place.

As you can see, a complete safety plan has to address the physical environment, the machinery itself, and the actions of your team.

Engineering Controls That Redesign for Safety

Engineering controls are the gold standard. Why? Because they remove the hazard at its source or create a physical barrier, which means you're not just relying on people to remember a rule. Instead of just telling people to be careful, these controls make the environment itself safer.

The main goal here is simple: separate forklift traffic from foot traffic as much as you possibly can. This is the single most effective way to prevent collisions.

Some of the most effective engineering controls include:

- Physical Barriers: Installing guardrails, bollards, or fencing to create protected pedestrian-only walkways. This leaves no room for confusion about where people should walk.

- Designated Walkways: Painting highly visible, clearly marked crosswalks and pedestrian lanes. Use colors that contrast sharply with the floor so they can’t be missed.

- Proximity Sensors and Cameras: Equipping forklifts with tech that alerts operators to nearby pedestrians. Some advanced systems can even automatically slow or stop the lift when a person is detected in a high-risk zone.

- Warning Lights: Installing blue spotlights or red "safe zone" lights on forklifts. These project a bright light on the floor ahead of or around the vehicle, giving pedestrians a clear heads-up that a machine is approaching—especially around blind corners.

These solutions work because they don’t demand a split-second decision from a busy employee. The safety feature is always on, providing a constant layer of protection that stops accidents before they happen.

Administrative Controls That Define Safe Behavior

While engineering controls change the physical workspace, administrative controls change how people work within it. These are your formal policies, procedures, and rules that govern traffic flow and set clear expectations for both operators and pedestrians.

If engineering controls are the guardrails, administrative controls are the speed limits and traffic signs.

A well-defined Traffic Management Plan is the heart of your administrative controls. This is a comprehensive document that maps out the rules of your facility, leaving no room for guesswork. It isn't just a suggestion; it's the official playbook for safe movement.

Your plan needs to establish clear and enforceable rules for everyone:

- Speed Limits: Set strict speed limits for forklifts, especially in areas with pedestrian traffic, intersections, or blind corners. A common best practice is 3 mph in high-traffic zones.

- Stop and Go Procedures: Require operators to come to a complete stop and sound their horn at all blind intersections and before entering or exiting a building. No exceptions.

- "No-Go" Zones: Designate areas that are strictly off-limits to pedestrians unless they have specific authorization and follow approved safety procedures.

- Right-of-Way Rules: Clearly define that pedestrians always have the right of way. Operators must yield, make eye contact, and get a clear signal from the pedestrian before proceeding.

Comparison of Safety Control Measures

To help you decide where to focus your efforts, this table breaks down the two main types of safety controls.

| Control Type | Primary Goal | Examples | Effectiveness Level |

|---|---|---|---|

| Engineering Controls | Physically remove or isolate the hazard. | Guardrails, designated walkways, proximity sensors, warning lights, automatic braking systems. | High |

| Administrative Controls | Establish safe work practices and procedures. | Traffic management plans, speed limits, right-of-way rules, operator training, regular inspections. | Medium to High |

Engineering controls are generally more effective because they build safety directly into the environment, reducing the chance of human error. However, a strong safety culture relies on both. Administrative controls provide the critical framework of rules and training that make the engineered environment work as intended.

By implementing these administrative controls, you create a culture of accountability where safety isn't optional. It becomes a documented, trainable, and enforceable part of everyone's job, reinforcing the importance of forklift and pedestrian safety in every single action.

Building Your Forklift and Pedestrian Training Program

Engineering controls and administrative policies are great for shaping a safer physical environment, but they're only as good as the people working in it. You can have the most advanced facility in the world, but it won't matter without a team that understands the why behind every rule. Real safety is a shared responsibility, built on continuous education for everyone on your worksite.

Safety training can't be a one-and-done, check-the-box event. It has to be an ongoing commitment. The goal is to build a culture of vigilance where safe habits become second nature. This means developing distinct, thorough training programs for both forklift operators and the pedestrians who share their space.

Think about this: OSHA estimates that about 70% of forklift accidents in the United States could be prevented with more rigorous training policies. That number is staggering. It points to a massive gap where better education and stronger protocols can literally make a life-or-death difference.

Core Components of Operator Training

For forklift operators, training has to go way beyond learning to steer and lift. A truly competent operator isn't just a driver; they're a mobile safety hub, constantly aware of their surroundings. An OSHA-compliant program is the absolute minimum, but world-class safety demands more.

Your operator training should be a mix of classroom instruction, practical hands-on time, and a final evaluation of their performance in your actual work environment. Key modules have to include:

- Vehicle-Specific Knowledge: Covering the operating instructions, warnings, and quirks for the exact type of forklift the operator will use.

- Driving and Maneuvering: Hands-on practice steering, turning, and positioning—especially in tight spaces and with different load sizes.

- Load Management: Detailed instruction on load capacity, stability, and the physics of how a load’s center of gravity affects the machine’s balance.

- Situational Awareness: Training operators to actively scan for pedestrians, check blind spots, use the horn at intersections, and always make eye contact.

"A certified operator knows how to drive a forklift. A truly trained operator knows how to create a bubble of safety around their machine at all times, anticipating risks before they become incidents."

When you combine technical skills with a defensive driving mindset, you empower operators to be proactive safety leaders on the floor. Our guide on OSHA-compliant forklift training provides a deeper look into building a program that meets these standards.

Essential Training for Pedestrians

This is where so many facilities drop the ball. They focus intensely on operator training but completely forget the other half of the equation—pedestrians. It’s a huge mistake to assume people on foot instinctively know how to navigate a worksite filled with heavy machinery.

Pedestrian training is just as crucial for a complete safety program.

Everyone who works in or even just walks through your facility needs to understand the basic rules of engagement. This training doesn't have to be as intensive as operator certification, but it must be clear, consistent, and mandatory for all employees, visitors, and contractors.

Your pedestrian safety curriculum should include:

- Understanding Forklift Dynamics: Teach them about a forklift’s rear-wheel steering, its wide turning radius, and its massive blind spots. An analogy like comparing a forklift’s visibility to a car with blacked-out windows can really drive the point home.

- Using Designated Paths: Hammer home the rule that pedestrians must always use marked walkways and crosswalks. Shortcuts through operational areas should be a zero-tolerance policy.

- The "Eye Contact" Rule: Emphasize that pedestrians should never cross a forklift's path until they have made direct eye contact with the operator and received a clear signal (like a nod or hand gesture) to proceed.

- Avoiding Distractions: Implement a strict policy against walking while using a phone or wearing headphones that block out ambient noise and warning signals.

Ultimately, a robust training program transforms safety from a list of rules into a shared culture of awareness and mutual respect. When operators and pedestrians are both trained to look out for each other, you create an environment where everyone goes home safe.

Essential Gear and Equipment Maintenance

While you can re-engineer the entire workspace with administrative and engineering controls, the daily foundation of safety often comes down to two simple things: the gear people are wearing and the condition of the machines they’re working around.

Think of it this way: a well-designed highway is critical, but it’s the seatbelts, working brakes, and clear road signs that prevent individual accidents. The same exact logic applies in a busy warehouse. Personal Protective Equipment (PPE) and smart signage are your first line of defense, cutting through the noise to make hazards obvious.

When you pair that with rigorous, daily equipment maintenance, you start to build a predictable environment where safety becomes a reflex, not an afterthought.

Increasing Visibility with PPE and Signage

In a bustling warehouse, visibility is everything. A forklift operator needs every possible advantage to spot a pedestrian in a tight aisle, and a worker on foot needs clear, immediate cues to understand where the danger zones are. This is where high-visibility gear and no-nonsense signage make a huge difference.

High-visibility vests are a non-negotiable part of any serious safety program. Their fluorescent colors and reflective strips make people pop against the monotonous backdrop of pallets and steel, especially in dim light. It’s a simple piece of gear that can dramatically slash the risk of a pedestrian not being seen until it’s far too late.

At the same time, clear and simple signage acts as the traffic control system for your facility. These signs have to be understood at a glance.

- Speed Limit Signs: Post clear speed limits (like 3 mph) in high-traffic or pedestrian-heavy areas.

- Stop Signs: Use them at blind intersections and doorways to force operators to pause and look.

- Restricted Area Warnings: Use bold signs to mark off "Forklift Only" or "No Pedestrian Traffic" zones.

"A well-placed sign is a constant, silent reminder of the rules. It works 24/7 to reinforce the safe behaviors you teach in training, helping to build a culture of awareness one intersection at a time."

The Critical Role of Pre-Shift Inspections

A forklift with failing brakes or a broken horn isn't a tool—it's an uncontrolled hazard. This is why routine equipment maintenance is an absolute cornerstone of forklift and pedestrian safety. This isn't just about uptime; it's about preventing a mechanical failure from turning into a human tragedy.

The most important maintenance routine you have is the daily pre-shift inspection. OSHA requires this for a very good reason. Before an operator even thinks about starting their shift, they must run through a thorough check of the forklift's key safety components. This has to be a non-negotiable, documented process that confirms the machine is safe to run.

This daily checklist is an incredibly powerful tool for proactive safety. It empowers your operators to spot and report issues before they spiral out of control, making them active partners in the maintenance cycle. Even checking power levels on electric models is part of the process—having the right gear, including reliable forklift battery chargers, ensures every machine is ready for a safe shift.

A standard pre-shift inspection should always verify:

- Brakes: Test both the service and parking brakes to ensure they are fully functional.

- Horn and Alarms: Confirm the horn and any backup alarms are loud and clear.

- Lights: Check all warning lights, headlights, and any special safety lights like blue spots.

- Tires and Wheels: Look for proper pressure, any damage, or excessive wear.

- Forks and Mast: Inspect for cracks, bends, or any signs of hydraulic leaks.

By tying routine maintenance directly to accident prevention, you transform it from a tedious chore into a life-saving daily habit.

Fostering a Proactive Safety Culture

True forklift and pedestrian safety isn’t something you can just check off a list. It’s more than a collection of rules, new equipment, and a few training sessions. It’s a mindset—one that needs to be woven into the very DNA of your company.

The real goal is to build a proactive safety culture, where stopping an incident before it happens is valued far more than reacting after the fact. This means shifting your entire focus from assigning blame after an accident to learning from every single close call.

This cultural shift starts with how you treat near-misses. When a worker comes forward to report one, it shouldn't kick off a disciplinary process. It should be seen for what it is: a valuable, free lesson on where your system has a crack. Investigating these moments without blame encourages everyone to report them, giving you the critical data you need to fix problems before someone gets hurt.

Moving From Reactive to Proactive

A reactive culture is always one step behind. It waits for an injury to occur before taking action. A truly proactive culture, on the other hand, uses data and on-the-ground observation to stop that injury from ever happening. This involves tracking key performance indicators (KPIs) that actually measure the health of your safety program, not just the absence of accidents.

Here are a few key metrics worth monitoring:

- Near-Miss Reporting Rates: It might sound counterintuitive, but an increase in reported near-misses is often a great sign. It shows that your team trusts the system and feels safe speaking up.

- Completion of Safety Audits: Simply tracking how often safety walks and hazard audits get done ensures that vigilance becomes a consistent habit, not a one-off event.

- Corrective Actions Implemented: How fast are identified hazards being fixed? A long, lingering list of open issues is a clear signal that your process is broken somewhere.

By treating safety as an ongoing process of improvement rather than a destination, you create a system that is constantly learning and adapting. This is the hallmark of a resilient safety culture where every team member is an active participant.

Tying It All Together for Lasting Safety

Ultimately, a strong culture is where all the pieces we've discussed—engineering controls, administrative policies, training, and maintenance—finally click into place and work in harmony. Physical barriers protect the walkways, clear rules govern traffic flow, and solid training ensures everyone knows their role inside and out.

Daily inspections guarantee the equipment is safe to operate, and a proactive mindset makes sure everyone is looking out for one another.

When this happens, every team member, from the forklift operator to the person walking the floor, feels a genuine sense of ownership. They understand that their actions directly impact the safety of their colleagues. This shared responsibility is the powerful force that sustains a safe workplace for the long haul.

For more resources on building this type of robust program, explore the comprehensive forklift and pedestrian safety training materials available from Flat Earth Equipment. This collective effort transforms your facility from a place governed by rules into a community protected by shared values.

Frequently Asked Questions

Even with a great safety plan in place, questions always pop up. Getting clear on these common points helps everyone—from operators to warehouse walkers—understand their role in keeping the floor safe. Here are some straightforward answers to the things we hear most often.

How Often Should We Conduct Refresher Training?

OSHA sets the floor with its requirement for forklift operator recertification every three years. But that's just the bare minimum. If you're seeing a jump in near-misses or sketchy habits during safety walks, it's time for a refresher, regardless of what the calendar says.

A good rule of thumb is to hold annual safety refreshers for everyone, not just the operators. This keeps the rules fresh in everybody's mind. And if an operator has an accident or is seen driving unsafely, they need retraining immediately. It’s all about reinforcing good habits before bad ones can take hold.

What Is the Best Way to Manage Safety in Small Spaces?

Tight, congested areas are hot spots for collisions, which makes having clear, strict rules absolutely critical. When space is at a premium, your best safety tools are strong administrative controls.

- Drop the Speed Limit: In those narrow aisles, a 1-2 mph speed limit isn't unreasonable.

- Create One-Way Streets: Where you can, make aisles one-way to kill the risk of head-on encounters.

- Boost Visibility: Install convex mirrors at blind corners. They give both drivers and pedestrians a much-needed heads-up.

- Ban Shortcuts: Have a zero-tolerance policy for pedestrians cutting through active forklift paths. Make the designated walkways the only option.

Putting these measures in place creates a much more predictable and controlled environment, which is exactly what you need when you're working in close quarters.

The single most effective rule for forklift and pedestrian safety is simple: always assume the other person does not see you. This mindset forces both parties to actively seek confirmation, like making direct eye contact, before proceeding.

Are Pedestrians Always Given the Right of Way?

Yes. In nearly every scenario you can imagine, the pedestrian has the right of way. Forklift operators have to be trained to yield to people on foot, period. They slow down, they stop, and they wait for the person to pass safely. This rule is designed to remove any doubt at intersections or in shared aisles.

The only real exception would be in a clearly marked "Forklift Only" zone where pedestrians shouldn't be in the first place. But the default mindset for every single operator should be that the pedestrian comes first. It’s a core principle of any strong safety culture and a non-negotiable for preventing serious injuries.

At Flat Earth Equipment, we provide the parts, rentals, and OSHA-compliant training you need to build and sustain a culture of safety. Equip your team with the right tools and knowledge to keep your worksite accident-free. Learn more and get the support you need at https://flatearthequipment.com.