Effective aerial lift training isn't just a box to check on a safety form—it's a fundamental investment in your people, your equipment, and your entire operation's efficiency. Think of it as the bedrock of a safe worksite. Proper training gives operators the skills and confidence to prevent accidents, stay compliant, and protect everyone on the job.

Why Proper Aerial Lift Training Is Essential

Letting someone operate an aerial lift without proper training is like handing the keys to a new driver and telling them to merge onto the freeway. It's a recipe for disaster. While these machines might look simple to use, the potential for catastrophic failure is incredibly high. Insufficient training is a direct line to serious incidents, from tip-overs and electrocutions to falls from height.

These accidents come with a devastating human cost, but the fallout for the business can be just as severe. A single incident can set off a chain reaction of costly project delays, crippling OSHA fines, and permanent damage to your company's reputation. This is where a structured aerial lift training program proves its worth.

The High Stakes of Compliance and Safety

Regulatory bodies like the Occupational Safety and Health Administration (OSHA) and standards organizations like the American National Standards Institute (ANSI) don't create rules just for the sake of it. Their guidelines are born from real-world incidents, designed to prevent the worst from happening again.

OSHA is the law of the land, requiring employers to train and certify every operator as competent. ANSI provides the technical "how-to" for equipment design and safe use, which heavily informs OSHA's regulations. Skirting these rules isn't just cutting corners; it's a direct violation of federal law.

A robust training program is your first and best line of defense. It builds a culture of vigilance, transforming compliance from a burden into a shared commitment to keeping every team member safe.

A Growing Market Demands Skilled Operators

The demand for skilled operators is exploding. The global market for aerial work platforms is projected to jump from USD 14.07 billion in 2025 to USD 32.63 billion by 2034. The construction sector alone accounts for over 45% of that use. This explosive growth underscores the urgent need for qualified professionals who can operate these machines safely and efficiently. You can dig into more data on the aerial work platform market from Precedence Research.

For an individual, earning an aerial lift certification is a major career boost, opening doors to better jobs and more responsibility. For a business, a well-trained workforce is the key to maintaining uptime, protecting expensive assets, and landing future contracts. It’s an investment that pays for itself over and over in safety, productivity, and peace of mind. For more on this, check out our guide to workplace safety protocols.

What a High-Quality Training Program Includes

A top-notch aerial lift training program isn't just about watching a few videos and getting a certificate. It's a structured experience that builds real competence and a healthy respect for the machine. Think of it like a sturdy bridge – it needs two solid pillars to be safe.

One pillar is the classroom or theoretical training. This is where operators build their mental toolkit, learning the why behind every safety rule. The second, equally vital pillar is the hands-on practical evaluation. Here, theory gets put to the test, proving an operator can walk the walk, not just talk the talk.

Any program missing one of these pillars is incomplete and simply doesn't meet the standard. You can't master a lift just by reading a manual, and you definitely can't do it by driving one around a parking lot without understanding its limits and dangers.

H3: Building the Mental Toolkit: The Theoretical Component

The first phase is all about building a strong foundation of knowledge. This isn't about memorizing dry regulations; it's about internalizing the physics and hazards of working at height so operators can make smart, split-second decisions on the job.

A solid curriculum has to cover a few key areas to get everyone on the same page.

- Understanding Lift Types: Explaining the real-world differences between scissor lifts, articulating boom lifts, and telescopic booms (all types of MEWPs), and when to use each one.

- Reading Load Charts: Teaching operators how to actually interpret a machine's capacity chart to prevent overloading—a primary cause of catastrophic tip-overs.

- Spotting Hazards: Training operators to recognize and deal with electrical hazards (like power lines), ground hazards (soft spots or slopes), and overhead obstructions.

- Emergency Procedures: Walking through the exact steps for an emergency, including how to operate the ground controls and use the emergency lowering systems.

This classroom work ensures that before an operator even touches the controls, they grasp the risks and responsibilities that come with the job.

H3: From Knowledge to Skill: The Practical Evaluation

Once the classroom theory is locked in, it's time to prove it. This is the hands-on part where an instructor watches and evaluates an operator's ability to control the lift safely and efficiently. It's the final exam where knowledge meets action.

The goal of the practical evaluation is simple: confirm the trainee can apply their classroom knowledge to safely perform the tasks expected of them in a real-world work environment. This is where competence is truly verified.

The hands-on assessment isn't a free-for-all. It needs to include several key demonstrations of skill, all done under the watchful eye of a qualified evaluator.

- Pre-Use Inspection: The operator must perform a complete walk-around, checking everything from fluid levels and safety features to welds and tires, and know how to document it.

- Work Area Hazard Assessment: Before moving an inch, the operator has to show they can survey the area for dangers—uneven ground, power lines, foot traffic, you name it.

- Proper Use of Safety Gear: This includes correctly fitting and inspecting a personal fall arrest system (PFAS) and attaching it to the designated anchor point. No exceptions.

- Controlled Maneuvering: The operator needs to skillfully navigate the lift through a set course, showing smooth control of all functions like driving, lifting, extending, and rotating.

Beyond just the topics covered, a quality program is also defined by the thought put into creating an effective training programme. This two-part approach—theory first, then practice—is the only way to ensure your certified operators are genuinely equipped to handle the machine with the confidence and safety your job site demands.

Understanding OSHA and ANSI Requirements

Navigating workplace safety regulations can feel like trying to read a map in a foreign language. When it comes to aerial lift training, two acronyms pop up more than any others: OSHA and ANSI. Getting a handle on what each one does is the first real step toward building a training program that's not just compliant, but genuinely safe and effective.

Think of it like this: OSHA is the law. The Occupational Safety and Health Administration is the government agency that writes the rules and enforces them. Their regulations, specifically 29 CFR 1926.453 for aerial lifts, aren't just good ideas—they're the law of the land, and ignoring them comes with serious penalties.

ANSI, on the other hand, is like the expert engineer who designs the industry's best-practice blueprints. The American National Standards Institute creates voluntary standards for how Mobile Elevating Work Platforms (MEWPs) should be designed, used, and maintained. While they are technically voluntary, OSHA frequently incorporates ANSI standards by reference, making them pretty much essential for staying compliant.

The Core Mandate: Who Needs Training?

The rule is crystal clear: anyone who operates an aerial lift needs to be properly trained and authorized by their employer. It doesn't matter if they're a seasoned pro or a total rookie.

And this isn't a one-size-fits-all deal. The training has to be specific to the type of lift the operator will actually be using. Just because someone is certified on a 19-foot scissor lift doesn't mean they're qualified to jump on a 60-foot articulating boom lift. The responsibility falls squarely on the employer to make sure an operator's training is current, relevant, and documented before they ever touch the controls.

At its heart, the OSHA mandate is about proving competence. It’s not enough to say an operator sat through a class; you have to be able to demonstrate they understand the risks and can safely handle the specific machine they're assigned to. That buck stops with the employer.

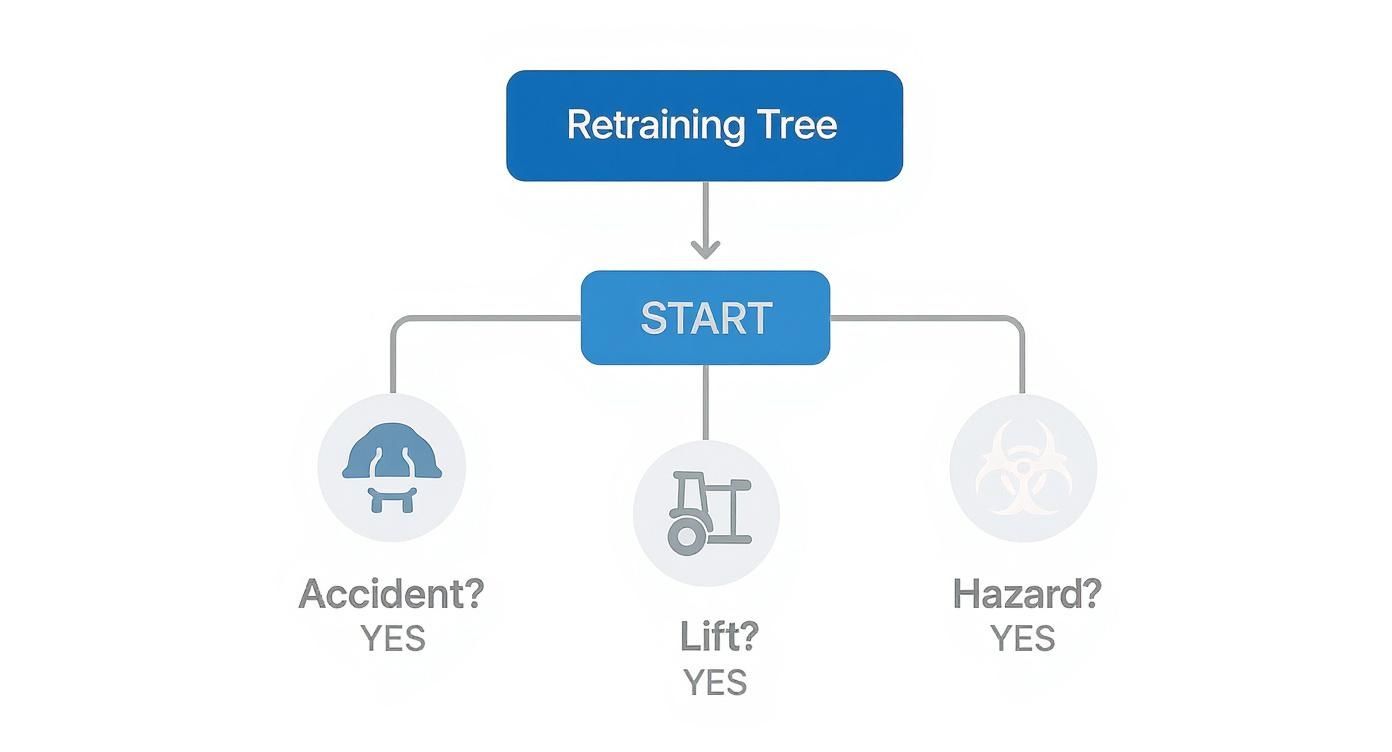

When Retraining Is Not Optional

Getting that first certification is just the starting line. OSHA is very clear that skills need to stay sharp, which is why they require retraining under certain conditions. This isn't something you can just pencil in for later; specific events trigger an immediate need for retraining and re-evaluation.

You can get more details from OSHA's official factsheet on aerial lift safety, but the triggers are straightforward.

- After an Accident or Near-Miss: If an operator is involved in any kind of incident, retraining is a must. The goal is to figure out what went wrong and reinforce the right way to do things.

- When New Hazards Appear: A worksite is a dynamic environment. If new risks pop up—like new overhead power lines or changing ground conditions—operators need to be trained on how to deal with them.

- Switching to a Different Lift: If you assign an operator to a new lift that's substantially different from what they're used to, they need machine-specific training. The controls and operating characteristics can vary wildly between models.

- Observed Unsafe Operation: If a supervisor or manager sees an operator doing something unsafe, that person has to be pulled from duty and retrained immediately. No exceptions.

Ultimately, OSHA and ANSI give you the playbook, but it’s up to the employer to run a solid aerial lift training program that lives up to those standards. This is about more than just dodging fines—it’s about building a culture of safety where every single operator has the knowledge they need to get home in one piece at the end of the day.

Choosing Between Online and In-Person Training

So, you're ready to get your crew certified, but the big question is how. Do you go with a traditional in-person class or a more modern online approach?

The truth is, there’s no single "best" way to do it. The right choice really comes down to what works for your team, your schedule, and your job sites. Let's break down the options.

The Rise of Online and Hybrid Models

Online aerial lift training has become a seriously powerful tool for getting the classroom theory done. Good online programs use videos, interactive modules, and quizzes to cover all the critical safety rules, machine parts, and OSHA standards.

The biggest win here is flexibility. Your operators can knock out the coursework whenever and wherever it works for them. This is a game-changer for companies running multiple shifts or managing crews spread out across different locations. It often cuts down on costs for travel, instructor fees, and the lost production from pulling everyone off a job for a full day.

Of course, you can't learn to drive a boom lift from a computer screen alone.

That’s why the smartest approach for most companies is a hybrid model. This combines the convenience of online learning for the theory with a mandatory, in-person practical evaluation to prove hands-on skills. You get the best of both worlds.

This blended format keeps you squarely in line with OSHA's requirements. Operators build their foundational knowledge online at their own pace, and then a qualified evaluator meets them on-site to confirm they can safely run the exact machine they'll be using every day.

Evaluating the In-Person Experience

Now, there's a reason the old-school, hands-on classroom training has stuck around. Having an experienced instructor right there in front of you is incredibly valuable.

Operators can ask questions the moment they pop up, and a good trainer can spot and correct a small mistake in someone's technique before it turns into a dangerous habit. When a whole crew trains together, they build a shared safety mindset and can learn from each other's questions. The main downsides? Logistics and cost.

- Scheduling Conflicts: Getting an entire crew in the same room at the same time can be a nightmare, often leading to project delays.

- Higher Costs: In-person training usually comes with a higher price tag, factoring in instructor fees, travel, and maybe even a facility rental.

- Geographic Limitations: Finding a qualified, technician-led trainer can be tough, especially if you're not in a major metro area.

Deciding between these formats isn't always easy. To help clarify, here's a direct comparison of the most important features.

Comparison of Training Formats Online vs In-Person

A head-to-head comparison to help you decide which aerial lift training format best suits your organization's needs.

| Feature | Online Training | In-Person Training |

|---|---|---|

| Flexibility | High: Self-paced, accessible 24/7. | Low: Fixed schedule and location. |

| Cost | Lower: No travel, facility, or instructor fees. | Higher: Instructor time, travel, and venue costs. |

| Pacing | Individual: Operators learn at their own speed. | Group: Pace is set by the instructor for the whole class. |

| Interaction | Limited: Typically via quizzes and support tickets. | High: Direct, real-time Q&A with instructor. |

| Practical Skills | Theory only: Requires a separate hands-on evaluation. | Integrated: Hands-on practice is part of the session. |

| Consistency | Very High: Standardized curriculum for everyone. | Variable: Depends on the individual instructor's style. |

Ultimately, both paths lead to the same goal: a competent operator. The key is choosing the one that removes the most friction for your business while still delivering quality instruction.

No matter which format you start with, training isn't a one-and-done event. Retraining is required based on specific triggers, as shown in this decision tree.

As you can see, things like an accident, a near-miss, or a switch to a new type of lift all demand fresh training. Your choice of format should support this ongoing need for skill verification and ensure every operator is confident and competent on the machine in front of them.

How to Select the Right Training Provider

Picking a partner for your aerial lift training is a decision that goes way beyond a simple price comparison. Not all certifications carry the same weight, and the quality of the instruction has a direct impact on how safe and competent your operators are. The right provider isn't an expense; it's an investment in a safer, more compliant job site.

Think of it like hiring a guide for a mountain expedition. You wouldn't pick someone who's only read books about climbing—you’d want a seasoned mountaineer who knows the terrain firsthand. The same logic applies here. The cheapest option often just checks the boxes, leaving your team with a piece of paper but not the deep, practical knowledge needed to handle real-world challenges.

Look for Instructors with Real-World Experience

The single most important factor in any training program is the person leading it. A great instructor is much more than a polished presenter reading off a slideshow. They need to be an experienced operator or technician who truly understands these machines inside and out.

An instructor with hands-on experience can share practical insights you just can't find in a textbook. They can answer nuanced questions, demonstrate techniques from muscle memory, and explain why certain procedures are critical, not just that they are.

When you're vetting a provider, ask about their instructors' backgrounds. How many years have they actually operated or serviced the equipment they're teaching? This expertise is the difference between a checklist-style course and a truly educational experience that builds confident, safety-minded operators. You can see how we put this into practice by reading about our team and our mission at Flat Earth Equipment.

Prioritize Modern and Verifiable Credentials

In today's fast-paced work environment, you need proof of certification that's immediate and reliable. A laminated card is fine, but modern providers offer much better solutions. Look for programs that issue digital certificates with instantly verifiable QR codes.

This feature is a game-changer for on-site compliance checks. A safety manager or site supervisor can scan the QR code on an operator's card with their phone and instantly pull up their training records. It confirms their qualifications in seconds, eliminates fraudulent cards, and makes safety audits a breeze.

Ensure Training Meets Your Workforce's Needs

A one-size-fits-all approach to training rarely works, especially when you have a diverse crew. Clear communication is the bedrock of safety, so it's vital to choose a provider who can bridge any language gaps.

Look for these essential features for your team:

- Bilingual Options: A provider offering courses in both English and Spanish ensures every team member can learn the material in the language they understand best. This simple feature drastically improves how well they absorb and remember critical safety information.

- Machine-Specific Familiarization: While training covers general principles, OSHA requires operators to be familiarized with the specific make and model of the lift they'll be using. Make sure your provider's program either supports this or gives you a clear path to complete this final, crucial step.

Ultimately, picking the right aerial lift training provider means looking past the price tag. By focusing on instructor expertise, modern verification methods, and accessible training options, you can build a partnership that delivers real operator competence, ensures lasting compliance, and fosters a true culture of safety across your organization.

Mastering Documentation and Record Keeping for Compliance

Running a top-notch aerial lift training program is only half the battle. The other half? Proving it. Think of your documentation as your company's compliance insurance policy. When an OSHA inspector shows up, these records are your first and best line of defense.

Without proper paperwork, even the most rigorous training program is invisible to a regulator. These files are the tangible proof that you've done your due diligence, ensuring every operator is qualified and competent to work safely at height.

What Your Training Records Must Include

A complete training file for each operator isn't just a good idea—it's non-negotiable. It's the portfolio that tells the story of their qualification. Whether you keep physical files in a cabinet or use a digital system, they need to be organized and accessible on a moment's notice.

At a bare minimum, every operator's record needs these three things:

- Written Exam: A copy of the completed test showing their score. This proves they understand the theory behind safe operation.

- Practical Evaluation Checklist: The detailed, hands-on skills checklist signed off by the evaluator, confirming the operator can actually handle the specific lift they'll be using.

- Signed Roster or Certificate: A document with the operator's name, training date, the trainer's name, and the types of equipment they're cleared to use.

Keeping these records buttoned up isn't just about avoiding fines. It's about building a culture of accountability that reinforces just how serious operating this machinery is. It protects your people and your business.

The stakes couldn't be higher. A NIOSH study on aerial lift incidents found that falls from scissor lifts alone were responsible for 78 fatalities in the U.S. over an eleven-year span. What's more, worker movement was a contributing factor in 46% of those falls. That data underscores why training—and the records that prove it happened—is so critical.

Managing and Maintaining Your Records

OSHA says you have to keep training records for as long as an operator is employed with you. A solid best practice is to hang onto them for at least three to four years, which aligns perfectly with the standard three-year certification cycle. This gives you a clear, continuous history of an operator's training and retraining. We cover similar principles in our guide to forklift safety training.

To get a handle on this, many companies now rely on compliance management software to automate the tracking and reminders. If you're managing records manually, a simple spreadsheet works wonders. Just create columns for the operator's name, training date, expiration date, and the next retraining date. Pop a calendar reminder in for three months before a certification expires—that gives you plenty of time to schedule a renewal without creating a gap in compliance.

Common Questions About Aerial Lift Certification

When it comes to aerial lift training, a few key questions pop up time and time again for operators and safety managers alike. Getting the right answers isn't just about checking a box—it's about keeping your crew safe and your site compliant. Let's clear up some of the most common points of confusion.

Think of it this way: your certification is a specific license from your current employer to operate their equipment. It’s not a universal pass. Just like your driver's license doesn't mean you can hop into a NASCAR race, a general certificate doesn't cover every lift in every scenario.

How Often Is Recertification Necessary?

This is easily the most common question we get. While OSHA doesn't stamp a hard expiration date on every certification, the industry standard is clear: operators should be recertified every three years. This keeps everyone's skills sharp and up-to-date with any changes in equipment or safety rules.

But that three-year clock can be cut short. Certain situations demand immediate retraining, no matter how recent the last certification was.

- An operator is involved in an accident or even a near-miss.

- New hazards are identified on the job site that weren't covered in the initial training.

- A supervisor spots an operator using a lift unsafely.

- The operator gets assigned to a completely different type of aerial lift.

Does My Certification Transfer to a New Job?

Here’s another big one, and the answer is a firm no. Your aerial lift certification is tied directly to the employer who issued it. When you start a new job, your new company is legally required to evaluate and certify you on their machines and for their specific work conditions.

Your previous experience is definitely a plus, but it's not a substitute. The new employer has to verify you're competent on the exact equipment you'll be using for them. It’s their way of making sure you know the controls, safety features, and unique risks of their fleet.

Your certification is tied to the employer who provided the training and evaluation. It is not a universal license that you carry from one company to the next. This rule ensures every employer takes direct responsibility for their operators' qualifications.

What Is the Most Common Operator Mistake?

The most common—and most dangerous—mistake is also one of the simplest to avoid: failing to perform a thorough pre-use inspection and a full hazard assessment of the work area. Too many operators get complacent and skip this critical first step, which is a leading cause of incidents.

Before ever raising the platform, an operator needs to run through a meticulous equipment check and scan the environment for power lines, slopes, potholes, or other ground obstructions. This simple, disciplined habit is the single best way to prevent the vast majority of accidents.

At Flat Earth Equipment, we provide the parts, rentals, and OSHA-compliant training you need to keep your operations safe and productive. Discover our technician-led support and precision-fit parts at https://flatearthequipment.com.