At its core, a 12 volt converter is a device that changes DC voltage from one level to another. Think of it as an electrical translator, stepping a car's 12V supply down to 5V for a USB device or boosting it up to 48V for heavy-duty equipment. It’s all about making sure every piece of electronics gets the exact voltage it needs to run safely and correctly.

What a 12 Volt Converter Actually Does

Imagine your vehicle's 12V battery is a powerful waterfall. Now, picture your sensitive electronics—like a GPS unit, laptop, or an LED light strip—as tiny water wheels. If you were to place those delicate wheels directly under the full force of that waterfall, they'd be destroyed in an instant. The raw power is just too much.

This is where a 12 volt converter comes in. It acts like a sophisticated valve, taking the waterfall's powerful flow and channeling it into a smaller, controlled stream. It skillfully transforms the battery's 12-volt output into the precise voltage your device was designed for, whether that means stepping it down to 5 volts or stepping it up to 24 volts. This job is critical for bridging the gap between a single power source and the many different electronics that rely on it.

Why You Can't Just Skip It

Without a converter, connecting mismatched devices is either impossible or flat-out dangerous. The whole point of this component is to ensure compatibility and safety in any DC electrical system. You see this principle in action everywhere:

- On the Water: Powering a 24V trolling motor from a standard 12V deep-cycle battery in a fishing boat.

- In Commercial Fleets: Running a 5V telematics device in a 12V utility truck to track location and performance.

- On the Job Site: Operating 48V auxiliary lights on an electric forklift that runs on a completely different system voltage.

- Off the Grid: Charging a USB-C laptop from a 12V solar-powered battery bank in a camper van.

In every case, the converter is the silent middleman ensuring every component gets the right amount of juice. It prevents system failures, protects your gear from getting fried, and ultimately makes everything work together reliably.

It's a common mix-up, but converters and battery chargers aren't the same thing. While both manage electricity, a converter modifies DC voltage for a device to use right now. A charger, on the other hand, is built specifically to replenish a battery's stored energy. You can learn more about industrial-grade battery chargers and see how they fit into the bigger picture.

Ultimately, a 12 volt converter is what unlocks the full potential of your DC power source. It allows a single battery to safely run an entire ecosystem of electronics, each with its own specific power needs.

Choosing Your Converter: Buck, Boost, and Beyond

Not all converters are built the same, and grabbing the right one is absolutely critical for your system’s performance and safety. Picking a 12 volt converter isn’t a one-size-fits-all deal; it’s about matching the right tool to the job. You'll mainly run into three types: Buck, Boost, and Buck-Boost, each designed to solve a very specific voltage puzzle.

Getting a handle on these is your first step toward building a reliable DC power system. Let’s break down how each one works with some real-world examples you can actually relate to.

The Buck Converter: Stepping Voltage Down

The most common workhorse you'll find is the Buck converter, also known as a step-down converter. Its job is simple but essential: take a higher input voltage and knock it down to a lower, stable output. Think of it like a pressure regulator on a water line, but for electricity.

Let's say you need to power a small, sensitive 5V GPS tracker from your truck's 12V battery. Hooking it up directly would fry it instantly. A Buck converter steps in to "buck" that voltage down, giving the tracker a safe and steady 5V supply.

- Common Use Case: Powering 5V telematics units in a 12V service vehicle.

- Key Function: Decreasing voltage from a higher level to a lower one.

- Analogy: A gearbox that reduces high engine RPMs to a slower, more powerful speed for the wheels.

This diagram shows how a 12 volt converter acts as the essential middleman between a power source and a device that needs a different voltage.

As you can see, the converter is the key piece that transforms the raw 12V battery power into a safe, usable voltage for something like a laptop.

The Boost Converter: Stepping Voltage Up

Next up is the Boost converter, or step-up converter, which does the exact opposite. It takes a lower input voltage and ramps it up to a higher one. This is a lifesaver when your power source just doesn't have enough juice to run a particular piece of equipment.

For instance, you might want to run a 24V trolling motor on a boat that only has a 12V battery system. A Boost converter takes that 12V input and efficiently "boosts" it to the required 24V, letting the motor run at full tilt without the hassle of adding a second battery.

The Versatile Buck-Boost Converter

But what happens if your input voltage is all over the place? A battery's voltage can dip under a heavy load or spike during charging. This is where a Buck-Boost converter really shines. This clever hybrid can step voltage up or down as needed to keep the output perfectly stable.

A Buck-Boost is ideal for systems with fluctuating power, like a solar panel setup where the voltage changes with cloud cover. It guarantees your sensitive electronics get a consistent voltage, no matter what the battery is doing. This flexibility makes it a powerful problem-solver in unpredictable electrical environments.

Comparing Common 12V Converter Types

To make the choice clearer, this table breaks down the primary functions and common use cases for each converter type. It's a quick way to see which one fits your specific needs.

| Converter Type | Primary Function | Common Applications | Key Consideration |

|---|---|---|---|

| Buck Converter | Steps voltage down (e.g., 12V to 5V) | Powering USB chargers, GPS units, telematics, and low-voltage electronics from a 12V source. | Most common and cost-effective for reducing voltage. |

| Boost Converter | Steps voltage up (e.g., 12V to 24V) | Running higher-voltage equipment like trolling motors or audio amplifiers from a 12V battery. | Essential when your device requires more voltage than your source provides. |

| Buck-Boost Converter | Stabilizes output by stepping voltage up or down as needed | Solar power systems, battery charging circuits, or any application with a fluctuating input. | The go-to solution for unpredictable power sources. |

Ultimately, the goal is to match the converter's function to your system's electrical demands for a safe and reliable setup.

Specialized Converters: Battery Isolators

Beyond these core types, you'll find specialized units built for specific jobs. A battery isolator, for example, is a smart converter used in vehicles with dual-battery systems, like work trucks or RVs. It lets the alternator charge both the main starting battery and a secondary "house" battery at the same time.

More importantly, it stops your auxiliary electronics from draining the starting battery, so you're never stranded. This tech is a must-have for anyone running power-hungry gear independent of the main vehicle system.

The growing demand for these devices in industrial and automotive fields is part of a larger trend. In fact, the standalone DC-DC converter market, which includes the 12 volt converter, is expected to grow from USD 413.2 million in 2025 to USD 835.9 million by 2035. You can explore detailed market growth projections to see just how much electrification is driving this demand.

How to Read a Converter Spec Sheet

Popping open a technical spec sheet can feel like trying to read a foreign language. It's just a wall of numbers and industry terms that seem designed to confuse. But buried in that data is the complete story of a 12 volt converter’s real-world capabilities, its breaking points, and how it will perform under pressure. Learning to read that story is how you pick a component that won't let you down.

Don't think of it as a dry list of numbers. A spec sheet is a resume for your converter. Each line item is a qualification, telling you exactly what jobs it can handle and how it behaves when things get tough. Let's translate the most important ratings into practical terms.

Voltage Input and Output Range

The first numbers you’ll usually spot are the voltage ranges. The input voltage range defines the window of power the converter can safely accept from your source. For a 12V system, you might see this written as 9V-18V DC. That range is critical because a "12V" battery is rarely ever putting out exactly 12 volts; its voltage sags as it discharges and climbs when it's charging.

On the other side of the equation, the output voltage is the steady, clean power the converter promises to deliver to your equipment. A spec sheet will list this as a hard number, like 24V DC, often with a tight tolerance (like ±1%). Getting this match right isn't optional—the wrong voltage can fry your equipment instantly.

Continuous vs Peak Current Rating

Current, measured in amps (A), is another deal-breaker, and it comes in two distinct flavors. Think of it like a marathon runner versus a sprinter.

- Continuous Current: This is the marathon runner. It's the maximum current the converter can supply, day-in and day-out, without breaking a sweat or overheating.

- Peak Current: This is the sprinter. It’s a short, powerful burst of much higher current the converter can handle for just a few seconds, perfect for starting up motors or compressors that demand a huge initial kick of power.

So, a converter rated for 10A continuous and 20A peak can run a 10-amp load all day long. But it can also handle that momentary 20-amp surge needed to get a pump motor spinning. Ignoring that peak requirement is one of the fastest ways to kill a converter.

A spec sheet isn’t just about numbers; it’s a blueprint for reliability. A high-quality converter will have detailed thermal ratings, efficiency curves, and clear safety certifications, giving you the confidence that it can handle the demands of a tough industrial environment.

Efficiency and Thermal Ratings

Efficiency is easily one of the most important specs, but it’s often overlooked. Shown as a percentage, it tells you how much of the incoming power actually becomes useful output power. Everything else just turns into waste heat.

The difference between an 85% efficient converter and a 95% one is massive in the real world. Powering a 100-watt load, the 85% unit burns 15 watts as heat. The 95% unit only wastes 5 watts. That means the more efficient converter runs cooler, puts less strain on your batteries, and will almost certainly last longer. For fleet managers, that higher efficiency adds up to real savings on energy and better reliability across all your equipment. As you review these specs, it can be helpful to see how they stack up against other components; for instance, you can learn more about the specifications of a 24V Green2 charger to see how these same principles apply.

Finally, the thermal rating (or operating temperature range) tells you the ambient temperatures where the converter will work reliably. An industrial-grade unit might be rated for -40°C to 85°C. That’s your guarantee that it won’t quit in a freezing warehouse or inside a scorching hot engine compartment.

Your Step-by-Step Converter Selection Checklist

Going from a list of technical specs to the right converter can feel like a shot in the dark. To turn that guess into a confident choice, you need a solid, repeatable process. This checklist is your practical guide, walking you through everything from basic power math to picking a tough, reliable 12 volt converter that’s a perfect match for your gear.

Think of it as your pre-flight checklist before kicking off a project. By walking through these steps, you’ll cut out the guesswork and make sure you haven’t missed a small detail that could cause a big headache later. It breaks a complex decision down into a series of simple questions.

Step 1: Calculate Your Total Power Needs

Before you can pick a converter, you have to know exactly what you’re powering. Start by adding up the total wattage for all the devices you plan to hook up. The formula is simple: Watts = Volts x Amps.

For example, if you’re powering a device that needs 5 Amps at 24 Volts, your power requirement is 120 Watts (5A x 24V). Always add a buffer of at least 20% on top of that. This accounts for any inefficiencies and keeps you from redlining the converter, which is key to making it last.

Step 2: Define Your Application Environment

Where is this converter going to live? A unit installed in a climate-controlled warehouse has a much easier life than one bolted to a forklift in a dusty lumberyard or on a boat getting hit with saltwater spray.

Here’s what to think about:

- Moisture and Dust: Is the converter going to get wet or be exposed to fine particles? Look for an IP (Ingress Protection) rating. Something like IP67 means it’s totally dust-tight and can handle being temporarily submerged in water.

- Vibration and Shock: Equipment on the move—like in service trucks or farm machinery—gets shaken around constantly. A true industrial-grade converter is built tough to handle these forces without failing.

- Temperature Extremes: Check the converter’s operating temperature range. A commercial-grade unit might be rated from -40°C to 85°C, ensuring it works just as well on a freezing winter morning as it does on a blistering summer afternoon.

Step 3: Identify Critical Safety and System Features

Once you have your power and environmental needs locked down, the final step is choosing the right features to protect your system. This is where you decide on the non-negotiables that will keep your valuable equipment safe.

Picking a quality converter isn’t just a technical decision—it’s a strategic one that directly impacts how reliable and safe your operation is. A unit with the right built-in protections is your best defense against costly downtime and fried equipment.

Ask yourself these final questions:

- Do I Need an Isolated Converter? If you’re powering sensitive electronics like computers, radios, or GPS units, an isolated converter is a must. It creates a physical barrier (galvanic isolation) that stops electrical noise and voltage spikes at the source from ever reaching—and destroying—your load.

- What Safety Protections are Required? The basics are over-voltage, under-voltage, short-circuit, and over-temperature protection. Think of these as an automatic safety net that shuts the converter down before a catastrophic failure can happen.

- Does It Meet Compliance Standards? For any commercial or industrial job, make sure the converter has the right safety certifications, like CE or UL. This is your proof that it’s been independently tested and meets recognized safety and performance standards.

The demand for reliable power conversion is only getting bigger. In fact, the 12 volt converter segment is a huge piece of the European power converters and inverters market, which hit a value of USD 17.54 billion in 2024. This market is expected to grow at a compound annual rate of 7.3% through 2031, driven by the massive shift toward electrification in vehicles and industry. You can dig into a detailed regional analysis of the power converter market to see these trends for yourself.

Converter Selection Checklist

Jumping from needs to a final product can be overwhelming. This table breaks the process down into simple, actionable questions to ensure you cover all your bases before making a purchase.

| Consideration | Question to Ask | Example/Importance |

|---|---|---|

| Input Voltage Range | What is the source voltage, and how much does it fluctuate? | A forklift battery might drop from 48V to 36V under load. The converter must handle this entire range. |

| Output Voltage & Current | What steady voltage and current (amps) does my equipment need? | A 12V radio needing 10A continuous requires a converter rated for at least 12A to provide a safety buffer. |

| Peak Current Demand | Does my device have a startup surge? | A motor might draw 30A for a split second at startup, even if it only runs at 10A. The converter must handle this peak. |

| Operating Environment | Will it be exposed to dust, water, vibration, or extreme temperatures? | For outdoor use on a tractor, an IP67-rated converter with a wide temperature range (-40°C to 85°C) is essential. |

| Isolation Requirement | Am I powering sensitive electronics that need protection from electrical noise? | Yes, for GPS, computers, or radios. An isolated DC-DC converter is crucial to prevent interference and damage. |

| Safety Certifications | Does this need to meet specific industry standards like CE, UL, or E-Mark? | Essential for commercial vehicles and industrial equipment to ensure compliance and safety. |

By working through this checklist, you systematically confirm that the converter you choose is not just compatible, but perfectly suited for the job you need it to do. It’s the best way to guarantee long-term reliability.

Wiring and Troubleshooting Your Converter Safely

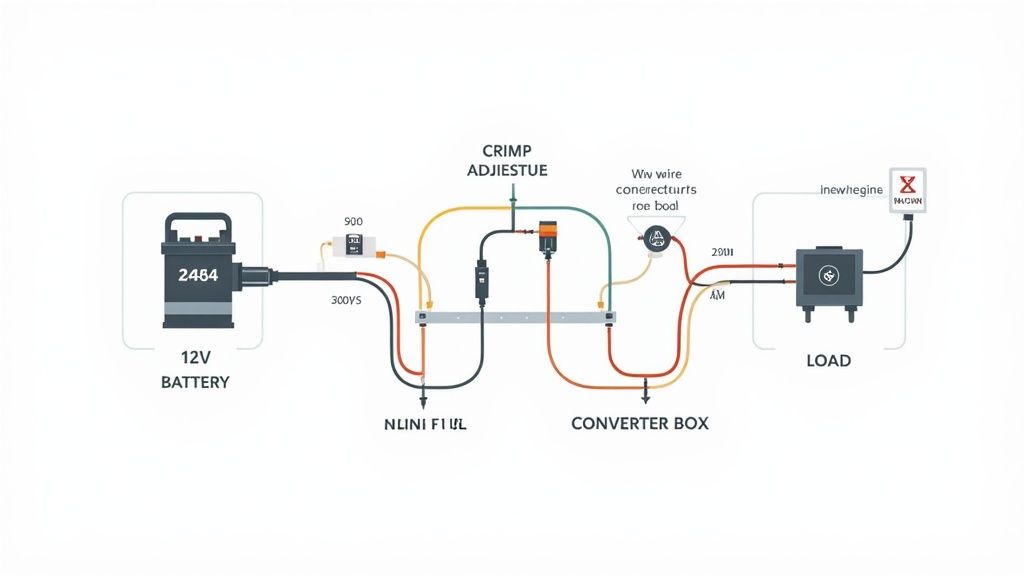

A top-tier 12 volt converter is only half the battle. Its real-world performance and lifespan depend entirely on a safe, solid installation. Bad wiring doesn't just hurt efficiency—it creates serious safety hazards, from overheating wires to total system failure. Getting this right isn't just about making things work; it's about building a reliable system that protects your gear and gives you peace of mind.

Proper installation starts with good components and even better connections. Think of the wiring as the circulatory system for your converter. Just like a heart needs clear, strong arteries, your converter needs properly sized wires and tough connections to deliver power without straining itself.

This attention to detail is what ensures your converter operates within its limits, maximizing its lifespan and preventing the kind of unexpected downtime that kills productivity.

Best Practices for Safe Wiring

Nailing the wiring from the start prevents the vast majority of common converter problems. If you focus on these three critical areas, you'll build an electrical foundation that's both safe and efficient.

Select the Correct Wire Gauge: Using a wire that's too thin is like trying to put out a five-alarm fire with a garden hose. It just can't handle the flow. This chokes the current, causing a major voltage drop and generating dangerous heat. Always use a wire gauge chart to match the wire size to your converter's amperage and the total length of the wire run. When in doubt, go with thicker wire (a lower gauge number)—it's always the safer bet for longer runs or higher currents.

Install an In-Line Fuse: This is completely non-negotiable. An appropriately sized fuse on the positive input wire is the single most important safety device in your system. It's designed to be the weak link—it blows and cuts the circuit during a short or overload, protecting your expensive converter and preventing a potential fire. Never, ever skip this step.

Ensure Secure Connections: Loose connections are the number one cause of electrical failures. Whether you're using crimp connectors, screw terminals, or something else, make sure every connection is rock-solid. On forklifts or other mobile equipment, vibration is a constant enemy that can work connections loose. Use high-quality, marine-grade connectors with heat shrink to create a durable, moisture-proof seal that will last.

A Simple Troubleshooting Guide

Even with a perfect installation, things can go wrong. When your 12 volt converter starts acting up, a logical, step-by-step approach will help you find the problem fast, without pulling your hair out.

Always start with the simplest explanations first. Don't immediately assume the converter itself is dead—most issues trace back to the power supply or the connections.

Troubleshooting isn't about guesswork; it's a process of elimination. By methodically checking each part of the system—from the power source to the load—you can isolate the fault efficiently and get your equipment back online faster.

Here's a common-sense checklist to run through:

No Power Output?

- Check Your Fuse: Is the in-line fuse blown? This is the first place to look and the most common culprit.

- Verify Input Voltage: Grab a multimeter and confirm the converter is actually getting the correct voltage from the battery. No power in means no power out.

- Inspect All Connections: Double-check that every input and output wire is tight. A loose ground wire is a frequent and often-overlooked problem.

Converter is Overheating?

- Check Your Load: Are you trying to pull more amps than the converter is rated for? An overloaded converter will run hot as it struggles to keep up, eventually shutting down or failing completely.

- Ensure Proper Ventilation: Converters generate heat and need airflow to cool down. Make sure it isn't crammed into a tight, unventilated box or covered by insulation.

- Confirm Wire Gauge: Undersized input wires get hot and force the converter to work harder than it should. Make sure your wiring is properly sized for the current you're pulling.

Putting 12V Converters to Work in Industrial and Fleet Vehicles

Forget about powering a laptop in an RV for a second. In the industrial world, a 12 volt converter is a genuine workhorse, thrown into environments that would destroy consumer-grade electronics. We’re talking constant vibration, wild temperature swings, and a daily diet of dust and moisture. Standard converters just aren't built to last.

For heavy-duty equipment—forklifts, utility trucks, agricultural machinery—you absolutely need an industrial-grade converter. Think of them as the all-terrain vehicles of the power conversion world. They are engineered from the ground up to survive the harsh reality of a job site.

Built for the Grind

So, what’s the real difference? It all comes down to construction. Industrial converters often boast high IP (Ingress Protection) ratings, like IP67. That rating guarantees the unit is completely sealed against dust and can even handle being submerged in water—a must-have for equipment that works outdoors or gets frequent wash-downs.

They're also mechanically tough. The internal electronics are often potted (encased in a solid compound) and housed in reinforced casings to absorb the relentless shock and vibration from heavy machinery. This isn't just about durability; it's about uptime. A failed converter can bring an entire operation to a halt. You can learn more about why robust electrical systems matter in our guide to forklift safety and maintenance.

In a fleet, a converter failure isn’t a minor hiccup—it’s a direct hit to your bottom line. Choosing a rugged, certified converter is a strategic move that protects your equipment investment and keeps expensive downtime at bay.

For fleet managers, the payoff goes beyond simple toughness. When you standardize on a single, high-quality converter model across your vehicles, you streamline everything. Maintenance becomes simpler, technicians get familiar with one installation process, and you only need to stock one type of replacement part. It cuts complexity and gets vehicles back in service faster.

This push for tougher, more efficient power solutions is a massive trend. The global market for power converters, which includes the humble 12 volt converter, was valued at around USD 20.65 billion in 2024. It’s projected to climb to nearly USD 31.21 billion by 2030, largely because of the intense electrical demands from the automotive and industrial sectors. Investing in the right components isn't just about keeping the lights on anymore—it's about future-proofing your entire operation.

Common Questions About 12 Volt Converters

Even with a solid grasp of the basics, a few specific questions always seem to pop up right when you're ready to buy or install a 12 volt converter. We get it. This section is your go-to reference for clear, direct answers to the most common queries we hear.

Think of this as a quick-fire Q&A to clear up any lingering confusion. We'll cover everything from the real-world impact of efficiency ratings to choosing the right converter type, helping you nail down those final details with confidence.

What Does an Efficiency Rating Really Mean for Me?

An efficiency rating tells you how much juice going into the converter actually comes out as usable power. The rest is just lost as heat. For example, a converter with 95% efficiency turning power for a 100-watt load wastes only 5 watts as heat. An 85% efficient model, on the other hand, burns off 15 watts.

This matters for two big reasons. First, higher efficiency means less wasted power—a huge deal in battery-powered systems like an RV or off-grid setup where every watt counts. Second, less waste heat means the converter runs cooler, which boosts its lifespan and reliability, especially when it’s tucked away in a tight spot with limited airflow.

Should I Choose an Isolated or Non-Isolated Converter?

The choice between an isolated and non-isolated converter really boils down to what you’re powering.

- Isolated Converters: These create a complete electrical break between the input and output. This is your insurance policy for protecting sensitive electronics like radios, computers, or GPS units from voltage spikes and electrical "noise" coming from the source.

- Non-Isolated Converters: These are more common and cheaper, perfect for running simple, tough loads like motors, lights, or pumps. Since there’s no electrical separation, they aren’t the right call for delicate electronics that could get fried by power fluctuations.

Here's a simple rule of thumb: If the device you're powering is expensive, sensitive, or has a microprocessor, an isolated converter is a small investment that prevents big, costly problems down the road.

Can I Use a Converter Rated for Higher Amps Than I Need?

Absolutely. In fact, it's often a smart move. Using a converter with a higher amperage rating than your device actually needs is perfectly safe. The converter will only supply the current that the device "asks for," no more.

For instance, if your equipment needs 8 amps, running it with a 12 amp converter is a great idea. That extra capacity gives you a safety margin, ensuring the converter runs cool and isn't constantly maxed out. This can seriously extend the unit's lifespan because it’s never straining to keep up. Think of it like using a heavy-duty pickup to haul a few bags of groceries—it does the job without breaking a sweat.

At Flat Earth Equipment, we provide industrial-grade components built for uptime and reliability. If you need a robust 12 volt converter that can handle the toughest conditions, explore our selection of precision-fit electrical systems. Get a fast quote on the parts you need at flatearthequipment.com.